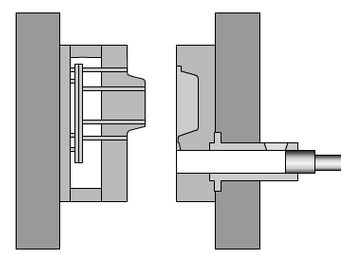

| Name | asm al-si alloys casts by die casting |

| Material Capabilities | Precious Metals,Stainless steel,Copper,Aluminum... |

| Type | Laser Machining, Milling, Other Machining Services, Turning, Rapid Prototyping |

| Surface treatment | Powder Coating,Zink Plating,Color Anodize,Electroplating... |

| Tolerance | 0.008-0.01mm |

| Process | Cnc Machining + Surface Treatment |

| Equipment | Milling Machine :3/4/5 Axis CNC Machining Center:Turning Centre |

| Quality Control | ISO/TS9001 |

| Name | Custom Machining Metal Parts Service |

| Place of Origin | China |

It usually involves the main processes: Centerless grinding,Beveling,Waterjet cutting,Painting,Anodizing,Deburring,etc. For turning, metal material is spun on a lathe, while CNC machines use cutting tools to remove excess material and shape the desired part. During the milling process, a CNC machine tool moves a cutting tool over the surface of a metal material to create the desired shape. Drilling involves using a rotating cutting tool to create holes in metallic materials.

One of the main advantages of metal CNC machining is its high level of precision and accuracy. Tight tolerances and repeatable results can be achieved using computer-controlled machines, making them ideal for manufacturing complex parts. It also increases the efficiency and speed of the manufacturing process compared to traditional manual methods.

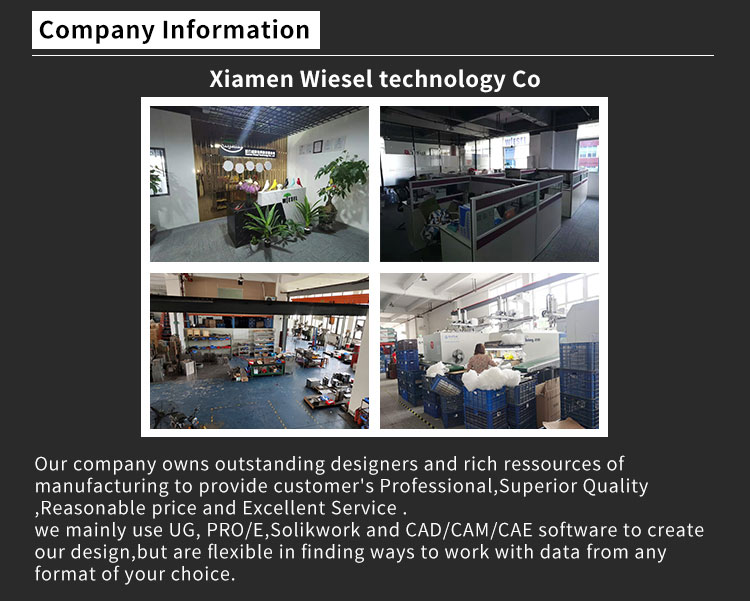

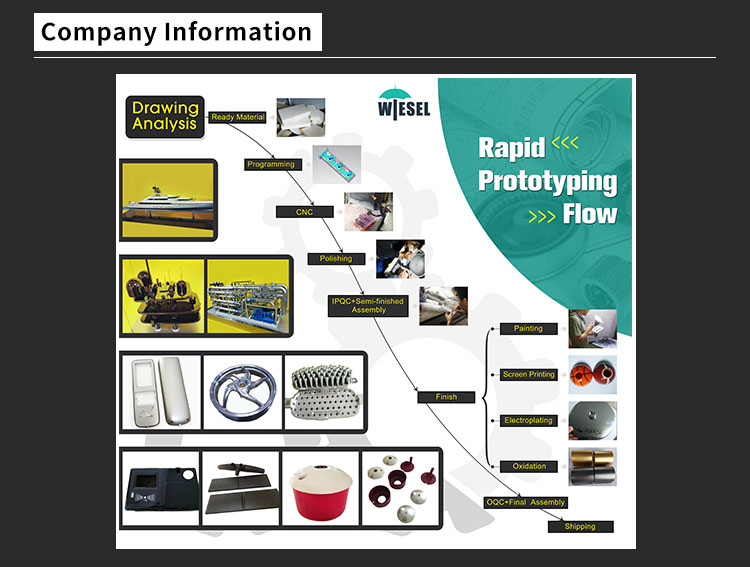

Our company information

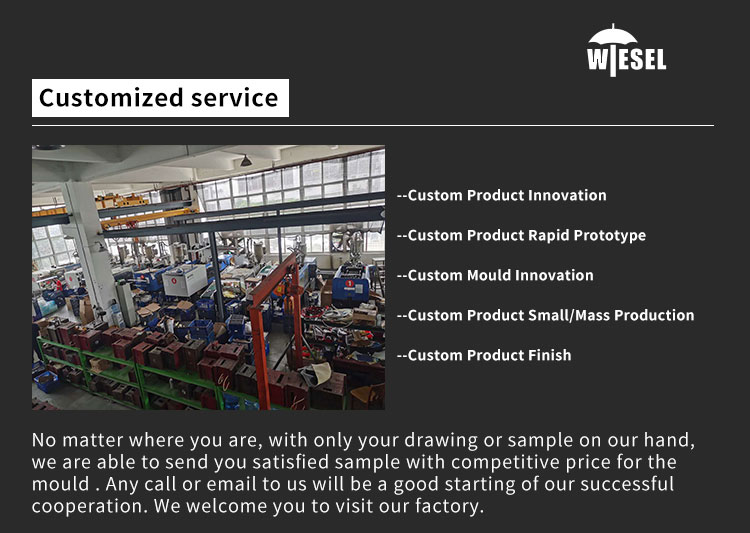

customized service

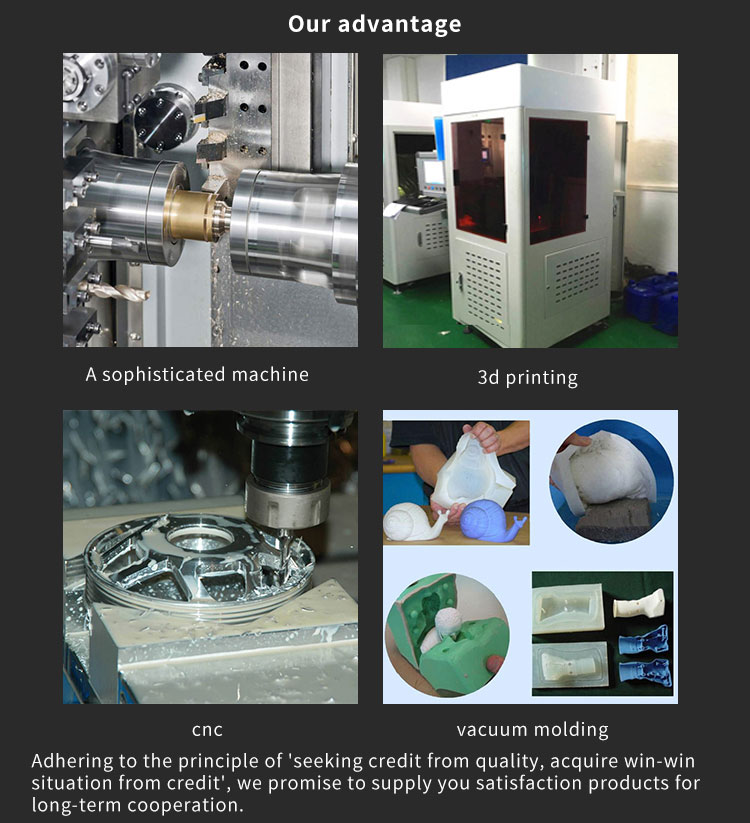

Our advantage

The packaging&shipping for asm al-si alloys casts by die casting