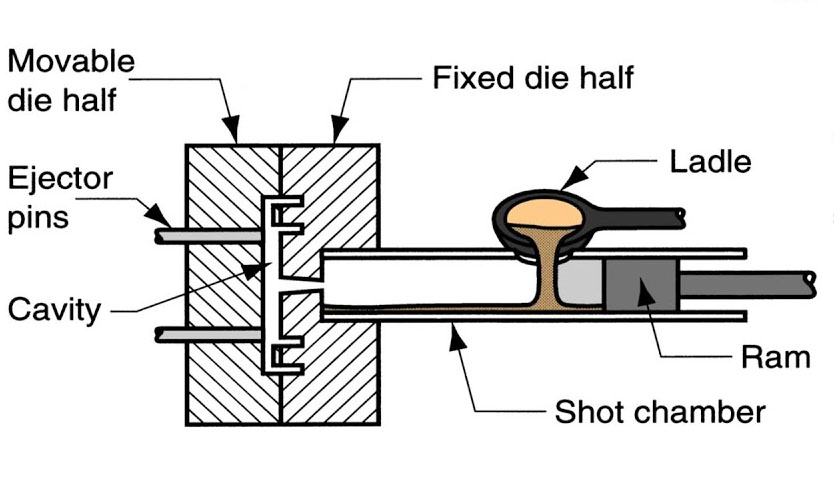

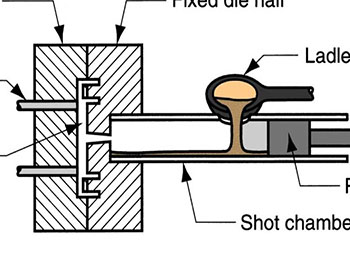

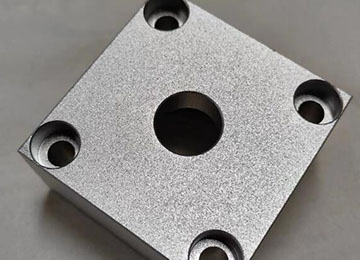

Die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mould cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used.

What's the type of die casting molding

How to work of Die-casting

|

|

|

|

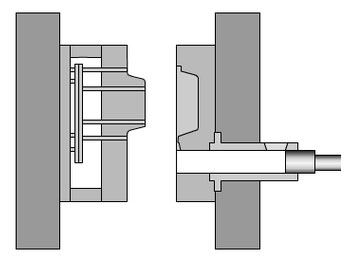

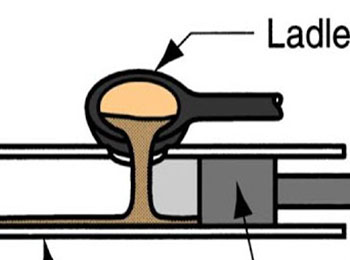

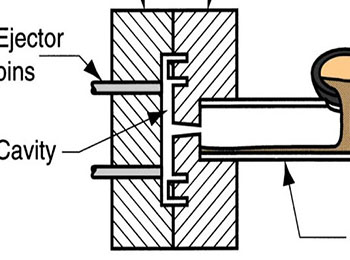

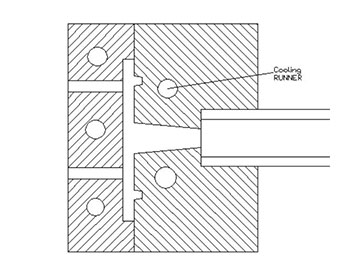

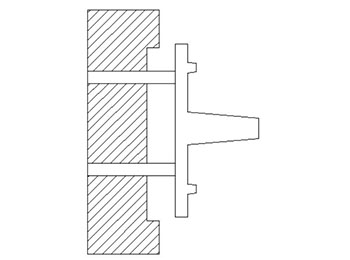

| Mold Preparation:Fixed the mold into the machine,usually consisting of two parts: the moved half and fixed half | Heating Molten Material: According to the required materials, heat metals (such as aluminum alloys,zinc alloys, ) to a suffficicient temperature to melt them into a liquid state. | Mold Closure: Merge the moved half and fixed half together to form a closed chamber | Injection Metal:Molten metal is injected into a closed mold through the die casting machine. the process is usually controlled by a hydraulic system to ensure that metal fills whote cavity |

|

|

|

|

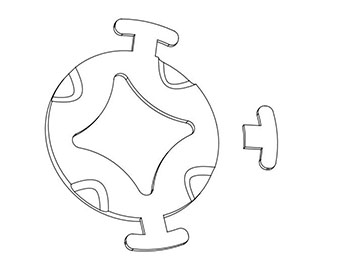

| Cooling and Solidification:After metal fills the mold, mold will be rapidly cooled by cooling water or other cooling media,causing the molten metal to solidify rapidly | Mold Opening:Once solidification is completed, the moved and fixed half will separate and uncover the meatl parts formed during the die-casting process | Flash removal and Processing:Remove any defective parts such as flash edges and excess materials.then,processing steps such as cutting, polishing, punching, | Surface treatment:Surface treatment of die-casting parts, such as painting,electroplating, anodizing, as needed to improve appearcance quality and anti-corrosion performance |

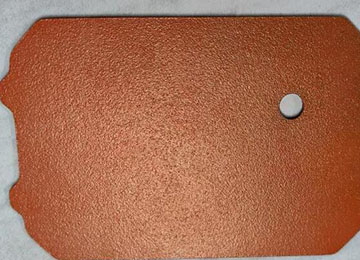

What's the main type of Finish for Die-casting Product

There are several main reasons for surface treatment of die-casting products:

Aesthetics and decoration: Through surface treatment, it can provide better appearance quality and decoration effect for die-casting products. For example, treatments such as spraying coatings, electroplating, or anodizing can present products with rich colors, glosses, and textures, enhance product aesthetics, and meet market demand and consumer aesthetic requirements.

Surface protection: Some metal materials are prone to oxidation, corrosion, wear, and environmental impact, and surface treatment can provide a protective layer to extend the service life of the product. For example, electroplating or coating can form a corrosion-resistant barrier on the surface of die-casting products to prevent metal oxidation or damage.

Improving functionality: Surface treatment can also improve the functionality of die-casting products. For example, special coatings can increase the friction resistance of products and provide better anti slip performance; Electroplating can improve conductivity and electromagnetic interference resistance.

Blocking defects: During the die-casting process, some defects may occur, such as bubbles, protrusions, defects, etc. By surface treatment, these defects can be covered or repaired, making the surface of the product smoother and more uniform.

Increase wear and corrosion resistance: Some surface treatment methods, such as coating, electroplating, etc., can improve the wear and corrosion resistance of products. This is very important for applications that require resistance to friction, chemical attack, or harsh environments, as it can extend the lifespan of the product and improve its performance.

|

|

|

|

| Spraying Coating | Electroplating | Anodizing | Power Coating |