Die Cast Zinc Alloy Mold is also commonly known as Dies. These molds are used for the mass-production of zinc alloy parts. Mold making used to be a difficult task before. Thanks to the CNC Machining technology mold making is now faster and more efficient than ever.

Zinc-alloy Die casting Mould requires a material that has higher strength and melting temperature than Zinc. Otherwise, the die will be damaged during the casting process. Usually, steel molds are used for Zinc die casting.

High-quality steel is quite costly and hard to machine. So, the die tooling cost is relatively high. Even though the high tooling cost,Zinc-alloy die casting toolings provides the best economy and quality for large volume production.

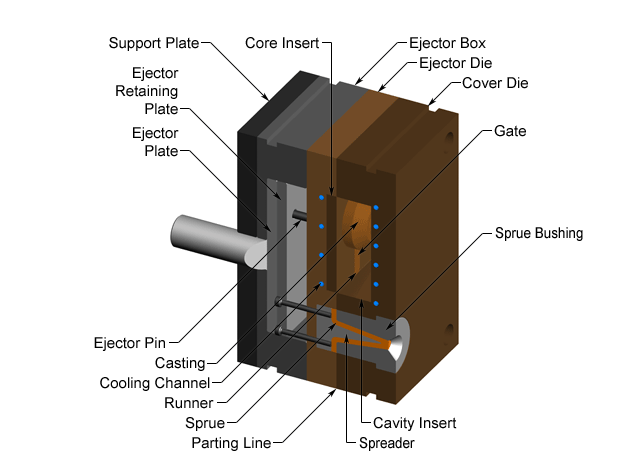

Components of Die Casting Mold

A Die Cast Mold consists of multiple parts with each serving a specific purpose. The main components in a die casting mold are listed below.

>>Cover Die

>>Ejector Die

>>Ejector Pin

>>Runner

>>Sprue

>>Cavity Insert

>>Ejector Plate

>>Support Plate etc.

Types of Die Cast Mold

>Production Dies

Production dies are used for large scale production. They are manufactured with high-quality, durable material to ensure longer die life. The initial tooling cost of production die is very high but the cost eventually drops with long term use.

>Prototyping Dies

These dies are mainly used for creating prototypes. The tooling process and functionality is the same as that of production dies. But the complex features are simplified and machined with less precision to minimize tooling cost.

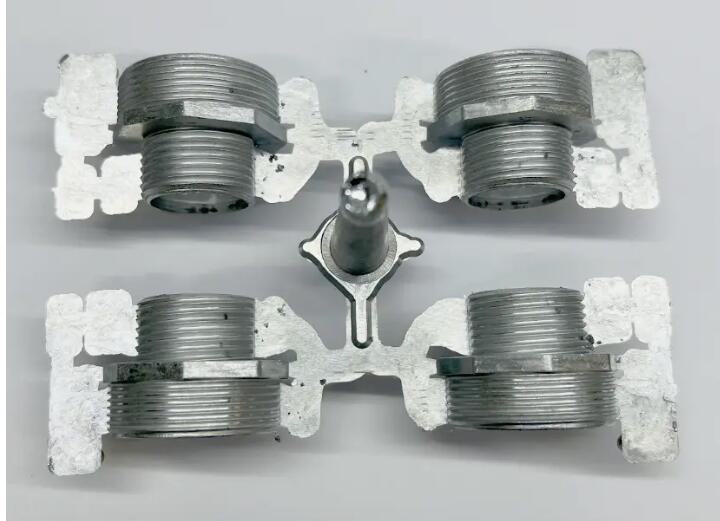

>Trim Dies

After a casting cycle ends, the parts have casting residue such as sprue, runners, risers, flash, etc. Trim dies are used for cutting down excess material from a completed die-casting. It is also used for separating the parts from a casting pattern.

Advantages of Zinc-alloy Die Cast Mold

Zinc-alloy die cast mould has made the production of Zinc-alloy parts a lot easier. Some of the benefits of die casting molds are explained below:

>A single mold can produce thousands of parts

>Can produce parts with very tight tolerances

>Can withstand high temperatures

>Can withstand very high pressure

>Significantly reduces production cost for large volume production

>Can manufacture multiple aluminum parts at one go

>Increased rate of cooling and solidification allows faster production

>For these multiple advantages, aluminum die-cast mold is being used for boosting aluminum die casting capacity.

Some Features of Zinc-alloy for Die casting

| Type | Hardness |

Tensile Strength |

Yield Strength | Impact Strength | Shear Strength | Elongation Rato |

| HB | MPa | MPa | J | MPa | %in 50mm | |

| Zamak3 | 82 | 283 | 221 | 58 | 214 | 10 |

| Zamak5 | 91 | 328 | 228 | 65 | 262 | 7 |

| Zamak7 | 80 | 283 | 221 | 58 | 214 | 13 |

| Zamak2 | 100 | 359 | 283 | 47 | 317 | 7 |

| ZA-8 | 103 | 374 | 290 | 42 | 275 | 10 |