Stamping mold is the process to exert pressure on the blank so that the blank will undergo steel transformation or separation to produce workpieces with fixed sizes, shapes and properties, stamping process can be divided into separating and forming.

produce workpieces with fixed sizes, shapes and properties, stamping process can be divided into separating and forming.

Main two types of Stamping Mold:

>>Single Engineering Die

>>Progressive Die ,Compound Die, Follow Die

Single Engineering Die

The Die is good for a simple part and the quantity is not large.Normally, it includes the below types:

|

|

|

| Blanking | Cutting | Piercing |

|

|

|

| Lancing | Trimming | Bending |

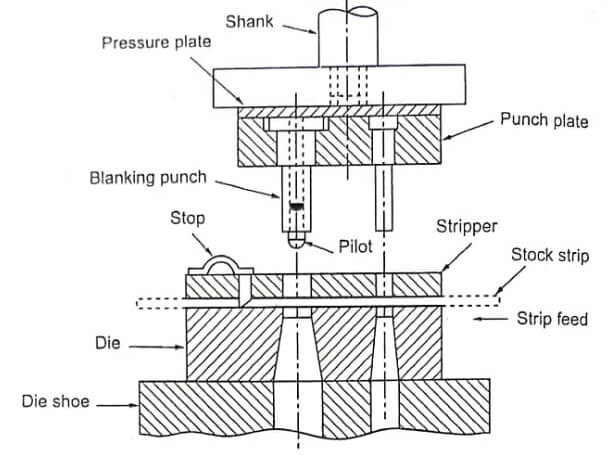

Progressive Die

Progressive die stamping is a stamping method that utilizes a series of stations installed across a die set. Each station is designed and configured to perform a specific stamping operation on the workpiece and, once it is completed, automatically move it along to the next station. As the workpiece makes its way through the various stations, it progressively takes on the desired shape and size.

|

|

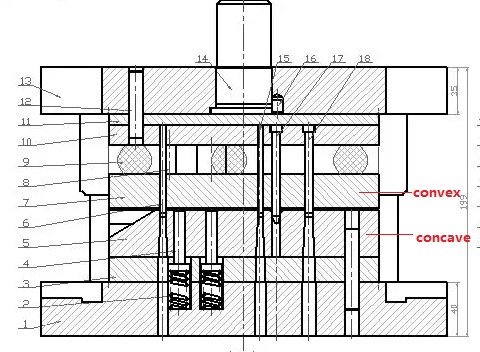

1. Working components

The convex and concave mold is the working part that directly makes the blank shape, therefore, it is the key part of the mold. The convex and concave mold is not only precise but also complex, it should meet the following requirements:

should meet the following requirements:

(1) It should have sufficient strength and cannot be broken or damaged during the stamping process;

(2) Appropriate requirements should be placed on its materials and heat treatment to prevent brittleness due to high hardness.

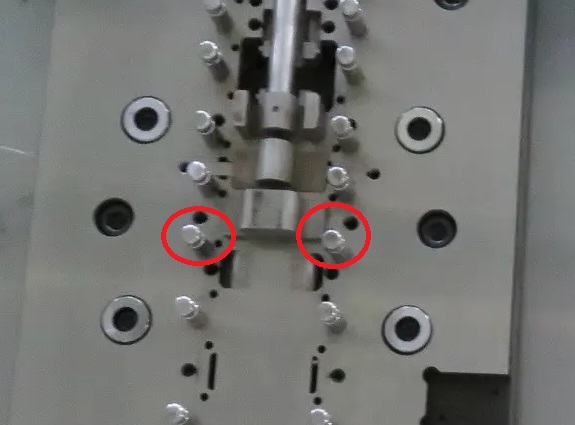

2. Positioning components

Positioning components are parts that determine the installation position of the blank. There are positioning dowel pins, stop pins, guide pins, guide bushings, fixed distance side knives, side presses, etc.

When designing positioning parts, you should consider the convenience of operation, there should be no positioning, and the position should be easy to observe. It is best to use forward positioning, outer profile positioning, and guiding pin positioning.

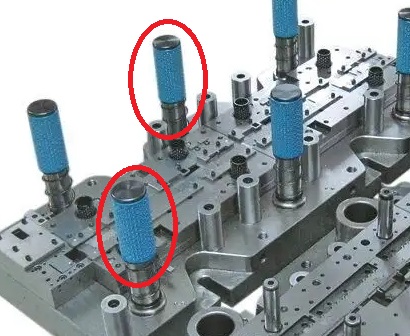

4. Guide components

Guide bushings and guide pins are the most widely used guide components. Its function is to ensure that the convex and concave dies have a precise fit clearance during the stamping work.

5. Support pillar and mold clamp

It includes upper and lower templates, mold handles, fixed plates for convex and concave molds, backing plates, stoppers, mold clamp, etc. The upper and lower templates are the basic components of the die; various other components are installed and fixed on it.

The plane size of the template, especially the front and rear direction, should be compatible with the workpiece, too large or too small is not conducive to operation.

Some molds (blanking, punching molds) need to set up a backing plate under the mold base for the convenience of parting. At this time, it is better to connect the backing plate and the template with screws, and the thickness of the two backing plates should be absolutely equal.

The spacing of the backing plates shall be subject to the parts that can be delivered and should not be too large to prevent the template from breaking.

6. Fasteners

It includes screws, nuts, springs, pins, washers, etc.

Standard parts are generally used. There are a lot of standard components of stamping dies, and the design and selection should ensure the needs of tightening and elastic ejection, avoiding the fasteners from being exposed on the surface operation position, and preventing hand injury and hindering operation.