What is CNC Plastic Machining?

In order to understand the breadth of experience Jaco has in CNC plastic machining, it’s important to also understand what “CNC” means. CNC stands for computer numerical control,

and is a machining process in which a pre-programmed computer software feeds directions to tools and machinery to create products. Because CNC machining is so effective, it’s used in a range of industries and processes. CNC machines can control grinders, lathes, mills, and more.

software feeds directions to tools and machinery to create products. Because CNC machining is so effective, it’s used in a range of industries and processes. CNC machines can control grinders, lathes, mills, and more.

Another benefit of CNC plastic machining is that it can allow three dimensional cutting tasks to be done in a single set of prompts. For that reason, it’s preferred for more complex parts. Manual machining requires that an operator be there to guide the machine(s) using levers and buttons. With CNC plastic machining, there is no longer the need for this extra person. This advanced method simply requires the right directions to feed to a machine, and it can complete tasks automatically.

CNC Plastic Machining Types

As mentioned, CNC machine for plastic productions can use a number of different tools and operations. Whether you need to complete PEEK CNC machining or a different type of CNC plastic process, here are some machines that may be utilized.

Lathes: A lathe machine cuts pieces in a circular direction using indexable tools. Using CNC plastic machining, the lathes carry out the cutting with precision and high velocity. When compared to manual machines, CNC plastic operations can produce far more complex designs that simply aren’t possible without this advanced technology.

Plasma Cutter: A plasma cutter works by using a plasma torch to cut material. As opposed to CNC machine for plastic productions, the plasma cutter is most often used in metal processing.

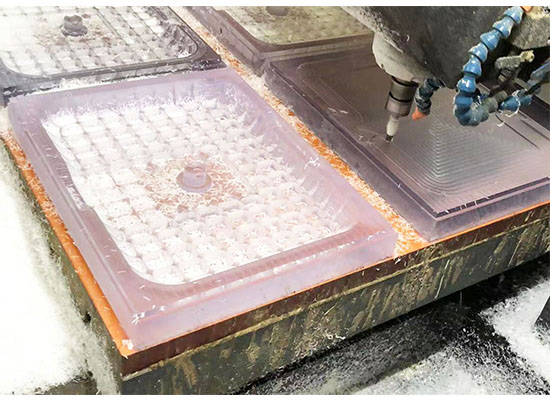

CNC Mills: A CNC mill runs based on number and letter prompts that guide pieces and parts across distances. The most basic CNC mills use a three-axis system (X,Y,Z) to shape parts. However, more advanced CNC plastic technology can sometimes incorporate up to three additional axes.

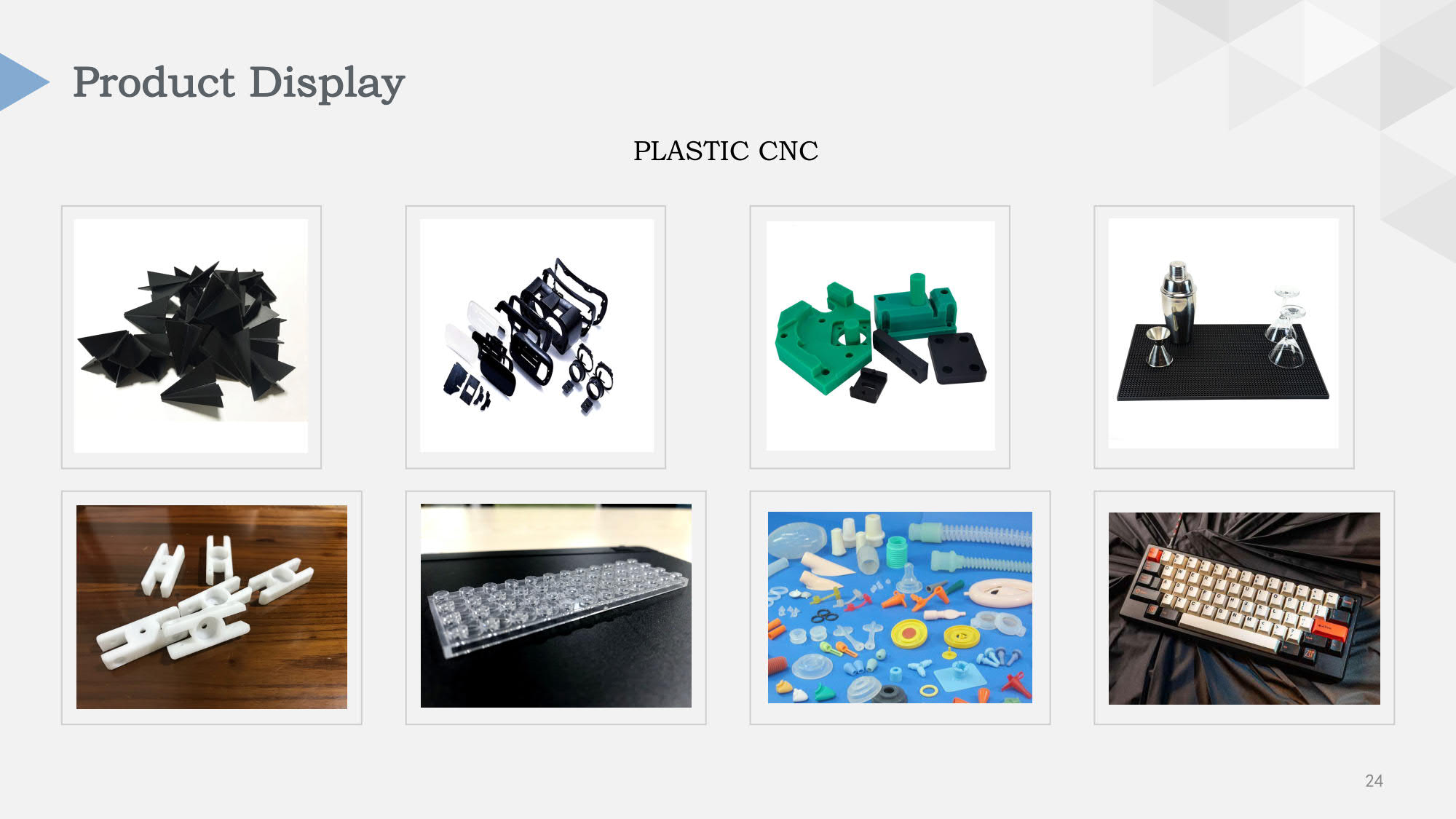

Plastic CNC Machining Parts

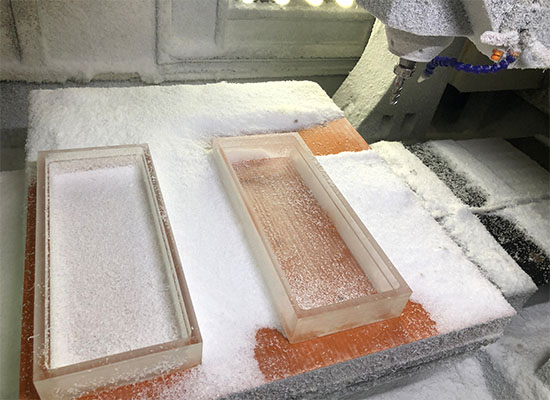

Although CNC machining can be used for a number of materials, Wiesel specializes in working with a range of plastics. CNC plastic machining is a subtractive manufacturing process that begins with a solid block of plastic. As the computer feeds the machine(s) directions, the block is cut and shaped down to its intended form.

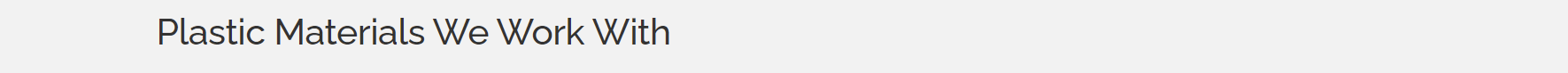

The cutting tools used for plastic CNC machining parts need to be precise and uniform. CNC machining is popular because it can replicate parts quickly and accurately no matter how complicated they are. CNC plastic machining works with incredibly tight tolerances to create a range of parts in industries like medicine, food and beverage services, and aerospace.So what materials can be used for plastic CNC machining parts? Here are some common machining plastics:

PEEK Plastic: PEEK CNC machining is one facet of plastic manufacturing that uses PEEK material to form pasts. PEEK is a high-performance thermoplastic that has excellent machining properties and can withstand chemical changes better than most other plastics.

Nylon: Nylon refers to a broad category of low-friction engineering thermoplastics that have a high impact strength. Nylon is often used for CNC plastic machining because it can withstand wear and tear and doesn’t react poorly to oil and fuel.

Delrin: Delrin is the shorthand name for acetal resins that are semi-crystalline thermoplastic polymers. When it comes to plastic CNC machining parts, Delrin is a popular choice because it can create stiff parts, has low friction, and has high dimensional stability.

| > Delrin | >PEEK | >Udel |

| >Nylon66,Nylon12 ,PA66+GF | >Polycarbonate (pc) | >UHMWPE |

| >HDPE,LDPE | >PTFE | >Acrylic |

| >FR-4 | >Teflon | >Ultem |

| >G-10 | >ABS | >Other custom |

|

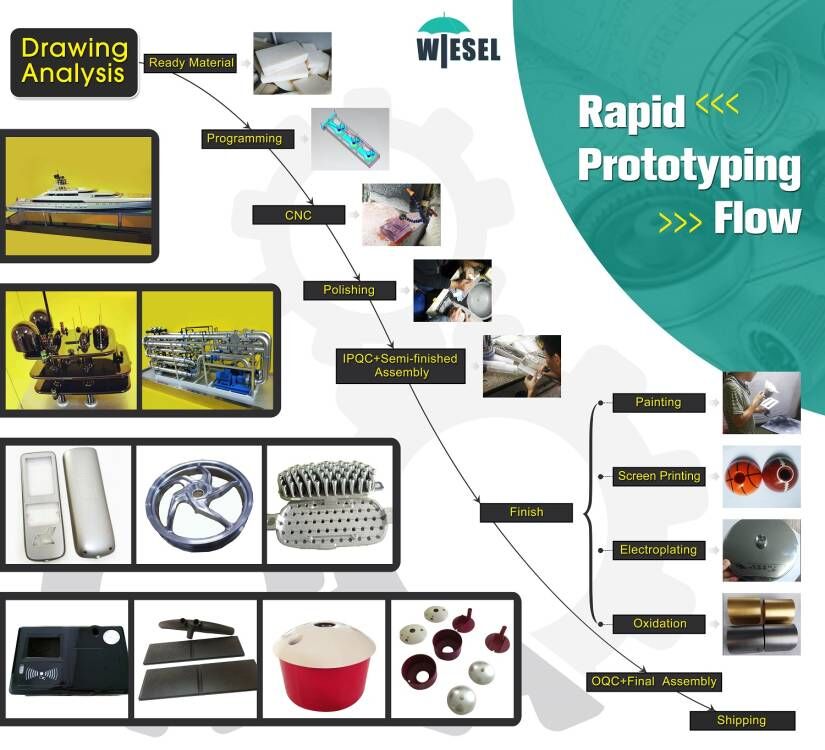

Rapid Prototyping Flow |

|