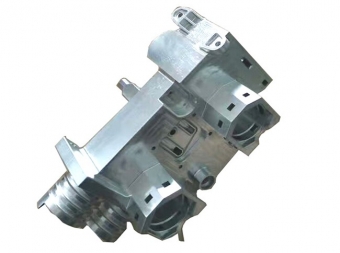

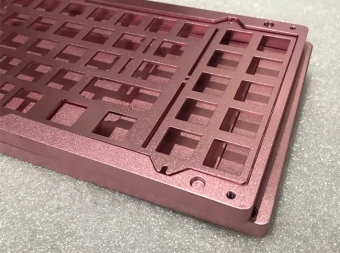

cnc plasma metal signs is versatile and can be used to create a variety of parts from simple to complex designs using a variety of metals including Silicon. The precision and consistency of these machines allows for tight tolerances and surface finishes to produce high-quality products and minimize waste.

The process begins with creating a digital design using CAD (computer-aided design) software. The design is then converted into machine instructions via CAM (computer-aided manufacturing) software. The CNC machine then uses these instructions to cut, shape and drill the metal material according to the design. One of the key advantages of cnc plasma metal signs is its ability to machine a variety of metals, including Brass alloy and titanium. This makes it a popular choice for parts production in various industries including Agriculture and medical.

| CNC Machining or Not | cnc plasma metal signs |

| Material Capabilities | Aluminum, Brass, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

| Type | Laser Machining, Milling, Other Machining Services, Turning, Rapid Prototyping |

| Surface treatment | Color Anodize,Sandblasting,Powder Coating,Electroplating,Zink Plating |

| Tolerance | 0.008-0.01mm |

| Process | Cnc Machining + Surface Treatment |

| Equipment | Milling Machine :3/4/5 Axis CNC Machining Center:Turning Centre |

| Quality Control | ISO/TS9001 |

| Name | Custom Machining Metal Parts Service |

| Place of Origin | China |

cnc plasma metal signs FAQs Guide. we will delve into the specifics of cnc plasma metal signs machining and explore its advantages, applications, and key considerations for successful implementation. Whether you are new to the field or looking to expand your knowledge, this guide will provide a comprehensive overview of this revolutionary manufacturing process. So, let's begin our journey into the world of cnc plasma metal signs machining!

1.Is it possible to add threading to a metal piece using CNC?

As one of the top cnc plasma metal signs manufacturers in China, we take this very seriously. Yes, it is possible to add threading to a metal piece using CNC. This is done by using a threading tool, which is a specialized cutting tool designed to cut threads into a workpiece. The threading tool is mounted in the spindle of the CNC machine and is programmed to cut the desired thread profile into the workpiece.

2.How does the rigidity of the machine affect the outcome of cnc plasma metal signs machining?

We continuously upgrade our skills and knowledge to adapt to changing cnc plasma metal signs market needs. The rigidity of the machine affects the outcome of metal CNC machining in several ways. A rigid machine will be able to hold the cutting tool in a more precise position, resulting in more accurate cuts and better surface finish. A rigid machine will also be able to handle higher cutting forces, allowing for faster cutting speeds and deeper cuts. Finally, a rigid machine will be less prone to vibration, which can cause poor surface finish and inaccurate cuts.

3.What are the common industries that utilize cnc plasma metal signs machines?

As one of the cnc plasma metal signs market leaders, we are known for innovation and reliability. 1. Automotive 2. Aerospace 3. Medical 4. Electronics 5. Defense 6. Marine 7. Tool and Die 8. Energy 9. Construction 10. Agriculture

4.What are the common applications of cnc plasma metal signs machining in the aerospace industry?

We have established a good reputation and reliable partnerships within the cnc plasma metal signs industry. 1. Aircraft engine components: CNC machining is used to create components for aircraft engines, such as turbine blades, compressor blades, and other engine components. 2. Aircraft structural components: CNC machining is used to create components for aircraft structures, such as fuselage frames, wing spars, and other structural components. 3. Aircraft landing gear components: CNC machining is used to create components for aircraft landing gear, such as landing gear struts, wheels, and other components. 4. Aircraft interior components: CNC machining is used to create components for aircraft interiors, such as cabin walls, seats, and other interior components. 5. Aircraft instrumentation components: CNC machining is used to create components for aircraft instrumentation, such as navigation systems, autopilot systems, and other instrumentation components.

5.What is the role of CAD software in cnc plasma metal signs machining?

cnc plasma metal signs is not a product only, but also can help you comes to money-making. CAD software is used to create 3D models of the parts that need to be machined. The CAD software is then used to generate the CNC code that will be used to control the CNC machine. The CNC code contains instructions for the machine to move the cutting tool around the part in order to create the desired shape. The CAD software also allows the user to simulate the machining process, which helps to ensure that the part will be machined correctly.

6.Can cnc plasma metal signs machines be used for both high and low volume production?

Yes, metal CNC machines can be used for both high and low volume production. CNC machines are highly versatile and can be programmed to produce a wide range of parts in both high and low volumes. They are also capable of producing parts with high precision and repeatability, making them ideal for both high and low volume production.

7.What are the advantages of using computer control in cnc plasma metal signs machining?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. 1. Increased Accuracy: Computer control allows for more precise machining than manual machining. This is because the computer can be programmed to make very precise cuts and can be adjusted to account for any errors that may occur. 2. Increased Speed: Computer control allows for faster machining than manual machining. This is because the computer can be programmed to make multiple cuts at once and can be adjusted to account for any errors that may occur. 3. Increased Efficiency: Computer control allows for more efficient machining than manual machining. This is because the computer can be programmed to make multiple cuts at once and can be adjusted to account for any errors that may occur. 4. Reduced Waste: Computer control allows for less waste than manual machining. This is because the computer can be programmed to make multiple cuts at once and can be adjusted to account for any errors that may occur. 5. Increased Safety: Computer control allows for safer machining than manual machining. This is because the computer can be programmed to make multiple cuts at once and can be adjusted to account for any errors that may occur.

8.How does the selection of the correct tool path affect the outcome of cnc plasma metal signs machining?

The selection of the correct tool path is critical to the success of metal CNC machining. The tool path determines the direction and speed of the cutting tool, as well as the amount of material that is removed. If the wrong tool path is chosen, the machined part may not meet the desired specifications, or the cutting tool may be damaged. Additionally, the wrong tool path can lead to an inefficient machining process, resulting in increased production costs.

9.What is the maintenance routine for a cnc plasma metal signs machine?

We operate our cnc plasma metal signs business with integrity and honesty. 1. Clean the machine regularly. 2. Check the lubrication levels and top up as needed. 3. Check for any loose bolts or screws and tighten them. 4. Inspect the cutting tools for wear and replace as needed. 5. Check the coolant levels and top up as needed. 6. Check the spindle bearings for wear and replace as needed. 7. Check the electrical connections and wiring for any signs of damage or wear. 8. Check the machine for any signs of vibration or excessive noise. 9. Check the machine for any signs of overheating. 10. Check the machine for any signs of corrosion or rust.

10.What are the most commonly used cutting tools in cnc plasma metal signs machining?

We have established long-term and stable partnerships with our suppliers, so we have great advantages in price and cost and quality assurance. 1. End Mills: End mills are the most commonly used cutting tools in metal CNC machining. They are used to cut slots, pockets, and contours in a variety of materials. 2. Drills: Drills are used to create holes in a variety of materials. They are available in a variety of sizes and shapes to accommodate different applications. 3. Reamers: Reamers are used to enlarge existing holes in a variety of materials. They are available in a variety of sizes and shapes to accommodate different applications. 4. Taps: Taps are used to create internal threads in a variety of materials. They are available in a variety of sizes and shapes to accommodate different applications. 5. Countersinks: Countersinks are used to create a conical shape in a variety of materials. They are available in a variety of sizes and shapes to accommodate different applications.

11.About cnc plasma metal signs payment method

Metal CNC payment methods vary depending on the supplier. Common payment methods include cash, check, credit card, PayPal, wire transfer, and ACH. Some suppliers may also accept cryptocurrency payments. It is important to check with the supplier to determine which payment methods are accepted.

12.Can cnc plasma metal signs machines be used for drilling, tapping, and countersinking?

Our mission is to provide customers with the best solutions for cnc plasma metal signs. Yes, metal CNC machines can be used for drilling, tapping, and countersinking. CNC machines are highly versatile and can be used for a variety of machining operations, including drilling, tapping, and countersinking.

13.How does the rigidity of the workpiece affect the accuracy of cnc plasma metal signs machining?

The rigidity of the workpiece affects the accuracy of metal CNC machining because it affects the stability of the cutting process. If the workpiece is not rigid enough, it can cause vibrations during the cutting process, which can lead to inaccuracies in the finished product. Additionally, if the workpiece is too rigid, it can cause excessive tool wear and reduce the accuracy of the machining process.

14.What are the environmental impacts of using different coolants in cnc plasma metal signs machining?

The environmental impacts of using different coolants in metal CNC machining depend on the type of coolant used. Generally, coolants used in metal CNC machining can be divided into two categories: water-soluble and oil-based. Water-soluble coolants are generally considered to be more environmentally friendly than oil-based coolants. They are biodegradable and do not contain hazardous chemicals. However, they can still cause environmental damage if not disposed of properly. Oil-based coolants are not biodegradable and can contain hazardous chemicals. They can also cause air and water pollution if not disposed of properly. Additionally, they can be flammable and can cause fires if not handled properly.

15.Can cnc plasma metal signs machines be used for both milling and drilling operations on the same piece?

Yes, metal CNC machines can be used for both milling and drilling operations on the same piece. This is because CNC machines are highly versatile and can be programmed to perform a variety of operations.

16.What is the role of chip control in cnc plasma metal signs machining?

As one of the top cnc plasma metal signs manufacturers in China, we take this very seriously. Chip control is an important part of metal CNC machining. It is the process of controlling the size, shape, and volume of chips produced during the machining process. This is done by controlling the cutting speed, feed rate, and depth of cut. Chip control helps to reduce tool wear, improve surface finish, and increase the life of the cutting tool. It also helps to reduce the amount of time and energy required to complete the machining process.

17.What are the safety measures for handling sharp edges in a CNC machine?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. 1. Wear protective clothing such as safety glasses, gloves, and long sleeves. 2. Ensure that the machine is properly guarded and that all safety devices are in place and functioning. 3. Keep hands away from the cutting area and use tools to adjust the cutting tool. 4. Use a push stick to move material away from the cutting area. 5. Use a vacuum to collect chips and dust. 6. Use a chip shield to protect the operator from flying chips. 7. Use a dust collection system to keep the air clean. 8. Keep the work area clean and free of debris. 9. Make sure the machine is properly lubricated and maintained. 10. Make sure the machine is properly grounded.