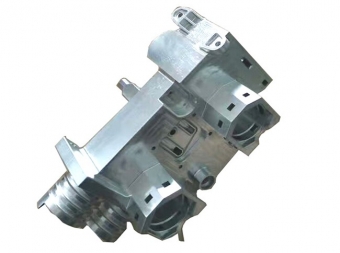

cnc precision metal machining part is a computer numerical control (CNC) machining process that uses rotating tools to remove material from a Cobalt chrome workpiece. The process is controlled by a computer program that uses precise measurements and instructions to achieve a high level of accuracy and repeatability.

One of the key attributes of cnc precision metal machining part technology is its ability to handle a wide range of metal materials, including aluminum, steel, titanium, Cobalt chrome, etc., making it suitable for a variety of industrial sectors such as Agriculture , the automotive and medical industries . With its precision and high-speed machining capabilities, it is able to produce complex designs and tight tolerances, meeting the demand for high-quality and customized metal parts. In terms of parameters, cnc precision metal machining part machine tools are equipped with multiple axes, usually three to five axes, providing a high degree of flexibility and operability for processing operations. These machines are also equipped with different types of cutting tools such as drills, $keyword{8}, end mills, and lathes to perform various cutting processes depending on the desired end product. Moreover, cnc precision metal machining part machine tools have a wide speed and feed rate control range, which can be adjusted for different materials and part characteristics to achieve the best cutting results. The accuracy of these machines is measured in microns, ensuring high precision and repeatability in production. In addition to these technical specifications, cnc precision metal machining part technology also offers automation and productivity advantages. By utilizing computer programming, human error is reduced and the production process is made faster and more efficient. It also allows for rapid prototyping and quick design changes, making it a cost-effective solution for low-volume and custom production.

| CNC Machining or Not | cnc precision metal machining part |

| Material Capabilities | Aluminum, Brass, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

| Type | Laser Machining, Milling, Other Machining Services, Turning, Rapid Prototyping |

| Surface treatment | Color Anodize,Sandblasting,Powder Coating,Electroplating,Zink Plating |

| Tolerance | 0.002-0.01mm |

| Process | Cnc Machining + Surface Treatment |

| Equipment | Milling Machine :3/4/5 Axis CNC Machining Center:Turning Centre |

| Quality Control | ISO/TS9001 |

| Name | Custom Machining Metal Parts Service |

| Place of Origin | China |

cnc precision metal machining part FAQs Guide. we will delve into the specifics of cnc precision metal machining part machining and explore its advantages, applications, and key considerations for successful implementation. Whether you are new to the field or looking to expand your knowledge, this guide will provide a comprehensive overview of this revolutionary manufacturing process. So, let's begin our journey into the world of cnc precision metal machining part machining!

1.Can cnc precision metal machining part machines produce high-quality surface finishes?

As one of the cnc precision metal machining part market leaders, we are known for innovation and reliability. Yes, metal CNC machines can produce high-quality surface finishes. CNC machines are capable of producing very precise and accurate parts with smooth surfaces. The quality of the surface finish depends on the type of tooling used, the speed and feed rate of the machine, and the type of material being machined.

2.Can cnc precision metal machining part machines be used for drilling, tapping, and countersinking?

Our mission is to provide customers with the best solutions for cnc precision metal machining part. Yes, metal CNC machines can be used for drilling, tapping, and countersinking. CNC machines are highly versatile and can be used for a variety of machining operations, including drilling, tapping, and countersinking.

3.Can cnc precision metal machining part machines be used for both large and small scale production?

cnc precision metal machining part is not a product only, but also can help you comes to money-making. Yes, metal CNC machines can be used for both large and small scale production. CNC machines are highly versatile and can be used to produce a wide range of products, from small components to large-scale parts. The size of the parts that can be produced is only limited by the size of the machine and the tools that are used.

4.About cnc precision metal machining part R&D capabilities

Metal CNC R&D capabilities are the ability to design and develop custom CNC machined parts and components from a variety of metals. This includes the ability to create complex shapes and features, as well as the ability to work with a variety of materials, such as aluminum, steel, brass, and titanium. CNC R&D capabilities also include the ability to create custom tooling and fixtures, as well as the ability to program and operate CNC machines. Additionally, CNC R&D capabilities include the ability to troubleshoot and repair CNC machines, as well as the ability to design and develop custom software for CNC machines.

5.About cnc precision metal machining part technology

Metal CNC technology is a process of machining metal parts using computer numerical control (CNC) machines. CNC machines are automated machines that are programmed to cut, shape, and finish metal parts with precision and accuracy. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. CNC technology is used to create complex parts with tight tolerances and intricate details. CNC machines are capable of producing parts with high accuracy and repeatability, making them ideal for mass production. CNC technology is also used to create custom parts for specific applications.

6.Is it possible to create complex shapes with cnc precision metal machining part machining?

We are a professional cnc precision metal machining part company dedicated to providing high quality products and services. Yes, it is possible to create complex shapes with metal CNC machining. CNC machining is a process that uses computer-controlled cutting tools to shape metal into a desired shape. CNC machining can be used to create complex shapes with intricate details, such as curved surfaces, holes, and slots.

7.What is the role of coolant in reducing heat and friction during cnc precision metal machining part machining?

Our cnc precision metal machining part products undergo strict quality control to ensure customer satisfaction. Coolant plays an important role in reducing heat and friction during metal CNC machining. Coolant helps to reduce the temperature of the cutting tool and the workpiece, which helps to reduce the amount of heat generated during the machining process. Coolant also helps to reduce friction between the cutting tool and the workpiece, which helps to reduce wear and tear on the cutting tool and the workpiece. Additionally, coolant helps to flush away chips and debris from the cutting area, which helps to reduce the risk of clogging and jamming.

8.What are the different types of tool changes used in cnc precision metal machining part machining?

1. Manual Tool Change: This is the most basic type of tool change and involves manually exchanging the cutting tool by hand. 2. Automatic Tool Change: This type of tool change is automated and is typically used in CNC machining centers. The tool is automatically exchanged by a robotic arm or a tool changer. 3. Quick Change Tooling: This type of tool change is used in CNC lathes and involves a quick-change tool holder that allows for rapid tool changes. 4. Tool Presetter: This type of tool change is used in CNC machining centers and involves a tool presetter that measures the tool and sets it to the correct position before it is used.

9.About cnc precision metal machining part customization services

Metal CNC customization services are a great way to create custom parts and components for a variety of applications. CNC stands for Computer Numerical Control, and it is a process that uses computer-controlled machines to cut and shape metal into the desired shape. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and industrial. CNC customization services can provide custom parts and components that are designed to meet the exact specifications of the customer. These services can also provide a variety of finishes, such as anodizing, powder coating, and plating. CNC customization services can also provide a variety of machining services, such as drilling, tapping, and milling.

10.About cnc precision metal machining part origin

Metal CNC origin is a term used to describe the process of using computer numerical control (CNC) machines to create metal parts and components. CNC machines are automated machines that use computer-controlled instructions to cut, shape, and form metal into a desired shape or size. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and industrial. CNC machines are used to create parts for a variety of applications, including medical implants, automotive components, and aerospace components.

11.What are the common industries that utilize cnc precision metal machining part machines?

As one of the cnc precision metal machining part market leaders, we are known for innovation and reliability. 1. Automotive 2. Aerospace 3. Medical 4. Electronics 5. Defense 6. Marine 7. Tool and Die 8. Energy 9. Construction 10. Agriculture

12.About cnc precision metal machining part MOQ

The MOQ for metal CNC machining depends on the complexity of the part and the material used. Generally, the MOQ is between 1 and 10 pieces. However, some suppliers may offer lower MOQs for certain parts or materials.

13.About cnc precision metal machining part inventory

Metal CNC inventory is a type of inventory that is used to store and manage metal parts and components that are used in CNC (Computer Numerical Control) machines. This type of inventory is typically used in manufacturing and engineering industries, as it allows for the efficient tracking and management of metal parts and components. Metal CNC inventory can include items such as screws, nuts, bolts, washers, and other metal components. It can also include raw materials such as steel, aluminum, and other metals.

14.Is it possible to perform reverse engineering using cnc precision metal machining part machining?

Yes, it is possible to perform reverse engineering using metal CNC machining. This process involves taking a physical object and using a CNC machine to create a 3D model of the object. This model can then be used to create a new version of the object or to modify the existing object.

15.What are the different types of cutting processes used in cnc precision metal machining part machining?

We focus on innovation and continuous improvement to maintain a competitive advantage. 1. Milling: This is the most common type of CNC machining process used for cutting metal. It involves using a rotating cutting tool to remove material from the workpiece. 2. Turning: This process is used to create cylindrical parts by rotating the workpiece and cutting tool against each other. 3. Drilling: This process is used to create holes in the workpiece by using a rotating cutting tool. 4. Boring: This process is used to enlarge existing holes in the workpiece by using a rotating cutting tool. 5. Reaming: This process is used to create a smooth finish on the inside of a hole by using a rotating cutting tool. 6. Tapping: This process is used to create internal threads in a hole by using a rotating cutting tool. 7. Broaching: This process is used to create internal shapes in a workpiece by using a rotating cutting tool.

16.How does the programming process differ between different cnc precision metal machining part machines?

cnc precision metal machining part is not a product only, but also can help you comes to money-making. The programming process for different metal CNC machines can vary depending on the type of machine and the complexity of the job. Generally, the programming process involves creating a program that tells the machine how to move and what operations to perform. This program is typically written in a language specific to the machine, such as G-code or Fanuc. The program is then loaded into the machine and the machine is set up to run the program. Depending on the complexity of the job, additional programming steps may be required, such as setting up tool paths, setting up work offsets, and setting up machine parameters.

17.About cnc precision metal machining part payment method

Metal CNC payment methods vary depending on the supplier. Common payment methods include cash, check, credit card, PayPal, wire transfer, and ACH. Some suppliers may also accept cryptocurrency payments. It is important to check with the supplier to determine which payment methods are accepted.

18.What safety precautions should be taken when handling metal pieces in a CNC machine?

We are a professional cnc precision metal machining part company dedicated to providing high quality products and services. 1. Wear protective clothing, such as safety glasses, gloves, and a face shield. 2. Ensure that the machine is properly grounded and that all electrical components are in good working order. 3. Make sure that the machine is properly lubricated and that all moving parts are free of debris. 4. Keep hands and other body parts away from the cutting area. 5. Use a vacuum to collect any metal chips or shavings that may be created during the machining process. 6. Make sure that the cutting tools are sharp and in good condition. 7. Use a coolant to reduce heat buildup and to reduce the risk of fire. 8. Make sure that the workpiece is securely clamped in place before machining. 9. Make sure that the machine is turned off and unplugged when not in use. 10. Make sure that the machine is properly maintained and inspected regularly.