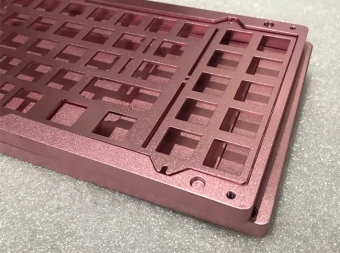

custom casted metal cnc milling is a computer numerical control (CNC) machining process that uses rotating tools to remove material from a Phosphorus bronze workpiece. The process is controlled by a computer program that uses precise measurements and instructions to achieve a high level of accuracy and repeatability.

During custom casted metal cnc milling machining, a solid block of metal is placed on the workbench and held in place. The CAD model is then uploaded to the CNC machine and the necessary cutting tools are selected. The machine then uses its programmed instructions to move the cutting tool in multiple axes, cutting away excess material and forming the desired shape. The use of CNC technology in metal processing offers many advantages. One of the main advantages is the ability to produce complex designs with high precision. This precision also maintains tight tolerances, allowing parts and components to fit together seamlessly. Additionally, CNC machining reduces human error, thereby reducing production time and costs. Metal CNC machining can be used to produce a variety of products, including prototypes, one-off custom parts, and high-volume production. It is commonly used in industries such as Entertainment and electronics, where precision and high-quality parts are critical.

| CNC Machining or Not | custom casted metal cnc milling |

| Material Capabilities | Aluminum, Brass, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

| Type | Laser Machining, Milling, Other Machining Services, Turning, Rapid Prototyping |

| Surface treatment | Color Anodize,Sandblasting,Powder Coating,Electroplating,Zink Plating |

| Tolerance | 0.004-0.01mm |

| Process | Cnc Machining + Surface Treatment |

| Equipment | Milling Machine :3/4/5 Axis CNC Machining Center:Turning Centre |

| Quality Control | ISO/TS9001 |

| Name | Custom Machining Metal Parts Service |

| Place of Origin | China |

custom casted metal cnc milling FAQs Guide. we will delve into the specifics of custom casted metal cnc milling machining and explore its advantages, applications, and key considerations for successful implementation. Whether you are new to the field or looking to expand your knowledge, this guide will provide a comprehensive overview of this revolutionary manufacturing process. So, let's begin our journey into the world of custom casted metal cnc milling machining!

1.What are the common applications of custom casted metal cnc milling machining in the medical industry?

1. Orthopedic Implants: Metal CNC machining is used to create orthopedic implants such as hip and knee replacements, spinal implants, and dental implants. 2. Surgical Instruments: Metal CNC machining is used to create precision surgical instruments such as scalpels, forceps, and clamps. 3. Medical Devices: Metal CNC machining is used to create medical devices such as stents, catheters, and pacemakers. 4. Prosthetics: Metal CNC machining is used to create prosthetic limbs and other body parts. 5. Diagnostic Equipment: Metal CNC machining is used to create diagnostic equipment such as MRI and CT scanners.

2.Is it possible to perform multiple operations on a single piece using custom casted metal cnc milling machining?

Yes, it is possible to perform multiple operations on a single piece using metal CNC machining. Depending on the complexity of the part, multiple operations such as drilling, milling, turning, and tapping can be performed on a single piece.

3.What are the common applications of custom casted metal cnc milling machining in the aerospace industry?

We have established a good reputation and reliable partnerships within the custom casted metal cnc milling industry. 1. Aircraft engine components: CNC machining is used to create components for aircraft engines, such as turbine blades, compressor blades, and other engine components. 2. Aircraft structural components: CNC machining is used to create components for aircraft structures, such as fuselage frames, wing spars, and other structural components. 3. Aircraft landing gear components: CNC machining is used to create components for aircraft landing gear, such as landing gear struts, wheels, and other components. 4. Aircraft interior components: CNC machining is used to create components for aircraft interiors, such as cabin walls, seats, and other interior components. 5. Aircraft instrumentation components: CNC machining is used to create components for aircraft instrumentation, such as navigation systems, autopilot systems, and other instrumentation components.

4.What safety precautions should be taken when changing tools in a CNC machine

Our company has many years of custom casted metal cnc milling experience and expertise. ? 1. Make sure the machine is powered off and the power cord is unplugged. 2. Wear protective gear such as safety glasses, gloves, and a face shield. 3. Secure the workpiece with clamps or other appropriate fixtures. 4. Disconnect any air lines or other connections to the machine. 5. Remove any loose tools or debris from the work area. 6. Make sure the tool holder is securely locked in place. 7. Use the appropriate wrench or other tool to loosen and remove the tool. 8. Inspect the tool for any damage or wear before installing it. 9. Make sure the tool is properly installed and securely tightened. 10. Reconnect any air lines or other connections to the machine. 11. Test the machine to make sure it is functioning properly.

5.Can custom casted metal cnc milling machines be used for both milling and drilling operations on the same piece?

Yes, metal CNC machines can be used for both milling and drilling operations on the same piece. This is because CNC machines are highly versatile and can be programmed to perform a variety of operations.

6.Can custom casted metal cnc milling machines be used for drilling, tapping, and countersinking?

Our mission is to provide customers with the best solutions for custom casted metal cnc milling. Yes, metal CNC machines can be used for drilling, tapping, and countersinking. CNC machines are highly versatile and can be used for a variety of machining operations, including drilling, tapping, and countersinking.

7.How does the cutting speed affect the temperature and surface finish in custom casted metal cnc milling machining?

The cutting speed affects the temperature and surface finish in metal CNC machining in several ways. A higher cutting speed will generate more heat due to increased friction between the cutting tool and the workpiece. This can lead to increased wear on the cutting tool, as well as increased temperatures in the cutting zone. Higher temperatures can also lead to a decrease in the surface finish of the machined part, as the increased heat can cause the material to deform and create a rougher surface. Additionally, a higher cutting speed can cause the cutting tool to vibrate, which can also lead to a decrease in the surface finish.

8.What are the advantages of using a gantry-style custom casted metal cnc milling machine?

1. High precision: Gantry-style metal CNC machines are designed to provide high precision and accuracy, allowing for complex and intricate designs to be created with ease. 2. Versatility: Gantry-style metal CNC machines are highly versatile and can be used for a variety of applications, including cutting, drilling, milling, and engraving. 3. Cost-effectiveness: Gantry-style metal CNC machines are cost-effective and can be used to produce large quantities of parts in a short amount of time. 4. Durability: Gantry-style metal CNC machines are designed to be durable and can withstand heavy use and wear and tear. 5. Safety: Gantry-style metal CNC machines are designed with safety features to protect operators from potential hazards.

9.About custom casted metal cnc milling technology

Metal CNC technology is a process of machining metal parts using computer numerical control (CNC) machines. CNC machines are automated machines that are programmed to cut, shape, and finish metal parts with precision and accuracy. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. CNC technology is used to create complex parts with tight tolerances and intricate details. CNC machines are capable of producing parts with high accuracy and repeatability, making them ideal for mass production. CNC technology is also used to create custom parts for specific applications.

10.Is it possible to add threading to a metal piece using CNC?

As one of the top custom casted metal cnc milling manufacturers in China, we take this very seriously. Yes, it is possible to add threading to a metal piece using CNC. This is done by using a threading tool, which is a specialized cutting tool designed to cut threads into a workpiece. The threading tool is mounted in the spindle of the CNC machine and is programmed to cut the desired thread profile into the workpiece.

11.What is the role of the spindle speed in custom casted metal cnc milling machining?

We are a professional custom casted metal cnc milling company dedicated to providing high quality products and services. The spindle speed is an important factor in metal CNC machining. It determines the speed at which the cutting tool moves across the material, and affects the quality of the finished product. A higher spindle speed will result in a faster cutting process, but can also cause the cutting tool to wear out faster. A lower spindle speed will result in a slower cutting process, but will also reduce the wear on the cutting tool. The spindle speed must be carefully adjusted to ensure the best results.

12.Is it possible to produce prototypes with custom casted metal cnc milling machining?

Our company has many years of custom casted metal cnc milling experience and expertise. Yes, it is possible to produce prototypes with metal CNC machining. CNC machining is a process that uses computer numerical control (CNC) machines to cut and shape metal parts with precision. It is a popular choice for producing prototypes because it is fast, accurate, and cost-effective.

13.How does the speed of the machine affect the production process?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. The speed of the machine affects the production process by determining how quickly the production process can be completed. Faster machines can produce more products in a shorter amount of time, while slower machines will take longer to produce the same amount of products. Faster machines also allow for more efficient use of resources, as they can produce more products with fewer resources. Additionally, faster machines can reduce the amount of time needed for setup and changeover, which can help to reduce costs and improve efficiency.

14.How long does it typically take to master the skills of custom casted metal cnc milling machining?

Our products & services cover a wide range of areas and meet the needs of different fields. The amount of time it takes to master the skills of metal CNC machining depends on the individual and the complexity of the parts being machined. Generally, it can take anywhere from a few months to a few years to become proficient in CNC machining.

15.How does the cutting fluid affect the overall efficiency of custom casted metal cnc milling machining?

Cutting fluids can have a significant impact on the overall efficiency of metal CNC machining. Cutting fluids can reduce friction between the cutting tool and the workpiece, which can reduce the amount of heat generated during the machining process. This can help to reduce tool wear and improve the surface finish of the machined part. Cutting fluids can also help to reduce the amount of time needed to complete a machining operation, as well as reduce the amount of energy needed to complete the operation. Finally, cutting fluids can help to reduce the amount of smoke and dust generated during the machining process, which can improve the working environment for the machinist.

16.Can custom casted metal cnc milling machines be used for both large and small scale production?

custom casted metal cnc milling is not a product only, but also can help you comes to money-making. Yes, metal CNC machines can be used for both large and small scale production. CNC machines are highly versatile and can be used to produce a wide range of products, from small components to large-scale parts. The size of the parts that can be produced is only limited by the size of the machine and the tools that are used.

17.What is the role of coolant in custom casted metal cnc milling machining?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Coolant plays an important role in metal CNC machining. It helps to reduce friction between the cutting tool and the workpiece, which helps to improve the cutting performance and extend the life of the cutting tool. Coolant also helps to reduce heat generated during the machining process, which helps to prevent the workpiece from warping or cracking. Additionally, coolant helps to flush away chips and debris from the cutting area, which helps to improve the surface finish of the machined part.

18.What are the advantages of using custom casted metal cnc milling over traditional machining methods?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. 1. Increased Precision: CNC machining offers greater precision than traditional machining methods, allowing for more accurate parts with tighter tolerances. 2. Increased Speed: CNC machining can produce parts faster than traditional machining methods, allowing for faster production times. 3. Increased Versatility: CNC machining can be used to produce a wide variety of parts with complex geometries, allowing for greater design flexibility. 4. Reduced Waste: CNC machining produces less waste than traditional machining methods, resulting in lower material costs. 5. Improved Safety: CNC machining eliminates the need for manual labor, reducing the risk of injury.

19.What are the factors to consider when choosing the right spindle speed for custom casted metal cnc milling machining?

1. Material: The type of material being machined will determine the optimal spindle speed. Harder materials require slower speeds, while softer materials can be machined at higher speeds. 2. Tooling: The type of tooling being used will also affect the spindle speed. For example, a high-speed steel tool will require a higher spindle speed than a carbide tool. 3. Feed Rate: The feed rate of the tool will also affect the spindle speed. A higher feed rate will require a higher spindle speed. 4. Depth of Cut: The depth of cut will also affect the spindle speed. Deeper cuts require slower speeds, while shallow cuts can be machined at higher speeds. 5. Machine Capacity: The capacity of the machine will also affect the spindle speed. Machines with higher capacities can handle higher spindle speeds.

20.Are there any environmental benefits to using custom casted metal cnc milling machining?

We continuously upgrade our skills and knowledge to adapt to changing custom casted metal cnc milling market needs. Yes, metal CNC machining can provide environmental benefits. CNC machining is a highly efficient process that produces very little waste, which helps to reduce the amount of material that needs to be disposed of. Additionally, CNC machining can be used to create parts with very precise tolerances, which can help to reduce the amount of energy needed to produce a part. Finally, CNC machining can be used to create parts with a longer lifespan, which can help to reduce the amount of materials that need to be replaced over time.