custom cnc metal parts quotation are equipped with specialized tools such as Ceramic cutting tool and grinders, which are programmed to rotate, rotate and move according to specifications set by the design software. This allows for precise shaping and cutting of different types of metals, including Tungsten.

custom cnc metal parts quotation machining usually involves the main processes: Buffing, milling and drilling. For turning, metal material is spun on a lathe, while CNC machines use cutting tools to remove excess material and shape the desired part. During the milling process, a CNC machine tool moves a cutting tool over the surface of a metal material to create the desired shape. Drilling involves using a rotating cutting tool to create holes in metallic materials. One of the main advantages of metal CNC machining is its high level of precision and accuracy. Tight tolerances and repeatable results can be achieved using computer-controlled machines, making them ideal for manufacturing complex parts. It also increases the efficiency and speed of the manufacturing process compared to traditional manual methods. Metal CNC machining is a versatile process suitable for a variety of metal materials, such as Palladium. It can be used in a variety of components including gears, shafts, brackets and housings in the Consumer goods and electronics industries.

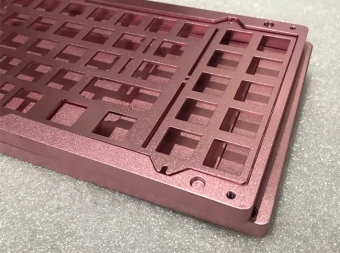

| CNC Machining or Not | custom cnc metal parts quotation |

| Material Capabilities | Aluminum, Brass, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

| Type | Laser Machining, Milling, Other Machining Services, Turning, Rapid Prototyping |

| Surface treatment | Color Anodize,Sandblasting,Powder Coating,Electroplating,Zink Plating |

| Tolerance | 0.001-0.01mm |

| Process | Cnc Machining + Surface Treatment |

| Equipment | Milling Machine :3/4/5 Axis CNC Machining Center:Turning Centre |

| Quality Control | ISO/TS9001 |

| Name | Custom Machining Metal Parts Service |

| Place of Origin | China |

custom cnc metal parts quotation FAQs Guide. we will delve into the specifics of custom cnc metal parts quotation machining and explore its advantages, applications, and key considerations for successful implementation. Whether you are new to the field or looking to expand your knowledge, this guide will provide a comprehensive overview of this revolutionary manufacturing process. So, let's begin our journey into the world of custom cnc metal parts quotation machining!

1.About custom cnc metal parts quotation production management system

Metal CNC Production Management System is a software solution designed to help metalworking companies manage their CNC production processes. It provides a comprehensive set of tools to help streamline production, from scheduling and tracking jobs to managing inventory and quality control. The system also helps to reduce costs by providing real-time visibility into production processes and helping to identify areas of inefficiency. Additionally, the system can be used to generate reports and analyze data to help improve production processes.

2.What is the role of the spindle speed in custom cnc metal parts quotation machining?

We are a professional custom cnc metal parts quotation company dedicated to providing high quality products and services. The spindle speed is an important factor in metal CNC machining. It determines the speed at which the cutting tool moves across the material, and affects the quality of the finished product. A higher spindle speed will result in a faster cutting process, but can also cause the cutting tool to wear out faster. A lower spindle speed will result in a slower cutting process, but will also reduce the wear on the cutting tool. The spindle speed must be carefully adjusted to ensure the best results.

3.About custom cnc metal parts quotation customization services

Metal CNC customization services are a great way to create custom parts and components for a variety of applications. CNC stands for Computer Numerical Control, and it is a process that uses computer-controlled machines to cut and shape metal into the desired shape. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and industrial. CNC customization services can provide custom parts and components that are designed to meet the exact specifications of the customer. These services can also provide a variety of finishes, such as anodizing, powder coating, and plating. CNC customization services can also provide a variety of machining services, such as drilling, tapping, and milling.

4.About custom cnc metal parts quotation payment method

Metal CNC payment methods vary depending on the supplier. Common payment methods include cash, check, credit card, PayPal, wire transfer, and ACH. Some suppliers may also accept cryptocurrency payments. It is important to check with the supplier to determine which payment methods are accepted.

5.How does a custom cnc metal parts quotation machine operate?

We focus on innovation and continuous improvement to maintain a competitive advantage. A metal CNC machine operates by using a computer to control the movement of the machine’s cutting tools. The computer is programmed with instructions that tell the machine how to move the cutting tools in order to shape the metal into the desired shape. The machine is also equipped with sensors that detect the position of the cutting tools and adjust the speed and direction of the cutting tools accordingly. The machine is also able to adjust the cutting speed and depth of the cut depending on the material being cut.

6.About custom cnc metal parts quotation delivery date

The delivery date for metal CNC parts will depend on the complexity of the parts, the size of the order, and the availability of the materials. Generally, the delivery time for metal CNC parts can range from a few days to several weeks.

7.About custom cnc metal parts quotation raw materials

Metal CNC raw materials are typically metals such as aluminum, steel, brass, and copper. These materials are used to create parts and components for a variety of applications, including automotive, aerospace, and medical. The raw materials are cut and shaped using CNC machines, which are computer-controlled machines that use a variety of tools to cut and shape the material. The raw materials are then machined and finished to create the desired product.

8.How does the precision of a custom cnc metal parts quotation machine compare to manual machining?

Being one of the top custom cnc metal parts quotation manufacturers in China, We attach great importance to this detail. The precision of a metal CNC machine is much higher than manual machining. CNC machines are able to produce parts with extremely tight tolerances and repeatable accuracy. Manual machining is limited by the skill of the machinist and the tools available. CNC machines are also able to produce parts with complex geometries that would be difficult or impossible to produce with manual machining.

9.About custom cnc metal parts quotation production capacity

Metal CNC production capacity is determined by the size and complexity of the parts being produced, the type of CNC machine being used, and the number of machines available. Generally, CNC machines are capable of producing parts with high accuracy and repeatability, and can produce parts with complex geometries. The production capacity of a CNC machine is determined by the number of axes it has, the speed of the spindle, and the size of the workpiece. The production capacity of a CNC machine can be increased by adding additional machines or by increasing the speed of the spindle.

10.How does the selection of the correct tool path affect the outcome of custom cnc metal parts quotation machining?

The selection of the correct tool path is critical to the success of metal CNC machining. The tool path determines the direction and speed of the cutting tool, as well as the amount of material that is removed. If the wrong tool path is chosen, the machined part may not meet the desired specifications, or the cutting tool may be damaged. Additionally, the wrong tool path can lead to an inefficient machining process, resulting in increased production costs.

11.Is it possible to create complex shapes with custom cnc metal parts quotation machining?

We are a professional custom cnc metal parts quotation company dedicated to providing high quality products and services. Yes, it is possible to create complex shapes with metal CNC machining. CNC machining is a process that uses computer-controlled cutting tools to shape metal into a desired shape. CNC machining can be used to create complex shapes with intricate details, such as curved surfaces, holes, and slots.

12.What are the cost factors to consider when using a custom cnc metal parts quotation machine for production?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. 1. Initial Cost: The initial cost of a metal CNC machine can vary greatly depending on the type of machine, its size, and its capabilities. 2. Operating Costs: Operating costs include the cost of electricity, coolant, and other consumables. 3. Maintenance Costs: Regular maintenance is necessary to keep a metal CNC machine running smoothly and efficiently. This includes regular inspections, lubrication, and replacement of worn parts. 4. Labor Costs: Labor costs include the cost of training operators and technicians, as well as the cost of labor for running the machine. 5. Tooling Costs: Tooling costs include the cost of cutting tools, fixtures, and other accessories. 6. Overhead Costs: Overhead costs include the cost of rent, insurance, and other overhead expenses.

13.About custom cnc metal parts quotation quality system

Metal CNC quality systems are designed to ensure that the parts and components produced by CNC machines meet the highest standards of quality and accuracy. Quality systems typically include a set of processes and procedures that are used to monitor and control the quality of the parts and components produced. These processes and procedures may include quality control checks, inspections, and testing. Quality systems also typically include a system of documentation and records that are used to track and monitor the quality of the parts and components produced. Quality systems are essential for ensuring that CNC parts and components meet the highest standards of quality and accuracy.

14.Is it possible to produce prototypes with custom cnc metal parts quotation machining?

Our company has many years of custom cnc metal parts quotation experience and expertise. Yes, it is possible to produce prototypes with metal CNC machining. CNC machining is a process that uses computer numerical control (CNC) machines to cut and shape metal parts with precision. It is a popular choice for producing prototypes because it is fast, accurate, and cost-effective.

15.About custom cnc metal parts quotation patent

Metal CNC patents are patents that cover the use of computer numerical control (CNC) machines to create metal parts. CNC machines are automated machines that use computer-controlled instructions to cut, shape, and form metal parts. CNC machines are used in a variety of industries, including automotive, aerospace, and medical. CNC patents cover the use of CNC machines to create metal parts, as well as the software and hardware used to control the machines. CNC patents also cover the use of CNC machines to create complex shapes and patterns.