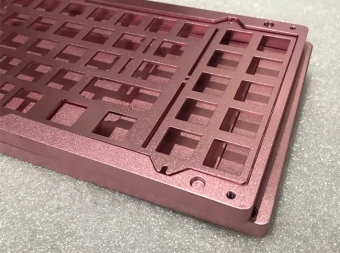

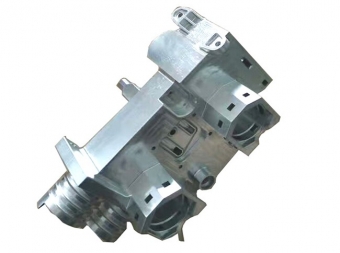

custom metal cnc machined parts factory is versatile and can be used to create a variety of parts from simple to complex designs using a variety of metals including Lead. The precision and consistency of these machines allows for tight tolerances and surface finishes to produce high-quality products and minimize waste.

The process begins with creating a digital design using CAD (computer-aided design) software. The design is then converted into machine instructions via CAM (computer-aided manufacturing) software. The CNC machine then uses these instructions to cut, shape and drill the metal material according to the design. One of the key advantages of custom metal cnc machined parts factory is its ability to machine a variety of metals, including Lead and titanium. This makes it a popular choice for parts production in various industries including Pharmaceutical and medical.

| Material: |

Aluminum (6061-T6, 6063, 7075-T6,5052) etc... Brass/Copper/Bronze etc... Stainless Steel (302, 303, 304, 316, 420) etc... Steel (mild steel, Q235, 20#, 45#) etc... Plastic (ABS, Delrin, PP, PE, PC, Acrylic) etc... |

| Process: | CNC Machining, CNC turning, CNC milling, CNC lathe machining, CNC boring, CNC grinding, CNC drilling etc... |

| Surface treatment: |

Clear/color anodized; Hard anodized; Powder-coating; Sand-blasting; Painting; Nickel plating; Chrome plating; Zinc plating; Silver/gold plating; Black oxide coating, Polishing etc... |

|

Gerenal Tolerance: (+/-mm) |

CNC Machining: 0.003 Turning: 0.007 Grinding(Flatness/in2): 0.003 ID/OD Grinding: 0.003 Wire-Cutting: 0.004 |

| Certification: | ISO9001:2008, ROHS |

| Production capacity: | depend on complicacy of different products and the quantity |

| Experience: |

15 years of CNC machining products 3 years of automation machine manufacturing |

| Packaging : |

Standard: pearl cotton and bubble bag, carton box and seal For large and big quantity: pallet or as per customers' requirement |

| Lead time : | In general:10-10days |

| Term of Payment: | T/T, Paypal, Trade Assurance etc... |

| Minimum Order: | Comply with customer's demand |

| Delivery way: | Express(DHL,Fedex, UPS,TNT,EMS), By Sea, By air, or on your requirement |

custom metal cnc machined parts factory FAQs Guide. we will delve into the specifics of custom metal cnc machined parts factory machining and explore its advantages, applications, and key considerations for successful implementation. Whether you are new to the field or looking to expand your knowledge, this guide will provide a comprehensive overview of this revolutionary manufacturing process. So, let's begin our journey into the world of custom metal cnc machined parts factory machining!

1.What are the common applications of custom metal cnc machined parts factory machining in the medical industry?

1. Orthopedic Implants: Metal CNC machining is used to create orthopedic implants such as hip and knee replacements, spinal implants, and dental implants. 2. Surgical Instruments: Metal CNC machining is used to create precision surgical instruments such as scalpels, forceps, and clamps. 3. Medical Devices: Metal CNC machining is used to create medical devices such as stents, catheters, and pacemakers. 4. Prosthetics: Metal CNC machining is used to create prosthetic limbs and other body parts. 5. Diagnostic Equipment: Metal CNC machining is used to create diagnostic equipment such as MRI and CT scanners.

2.Are there any limitations to the size of the metal piece that can be machined with CNC?

As one of the custom metal cnc machined parts factory market leaders, we are known for innovation and reliability. Yes, there are limitations to the size of the metal piece that can be machined with CNC. The size of the metal piece is limited by the size of the CNC machine, the size of the cutting tool, and the size of the workpiece. Additionally, the complexity of the part and the type of material being machined can also affect the size of the metal piece that can be machined.

3.What is the role of pre-programming in custom metal cnc machined parts factory machining?

Pre-programming is an essential part of metal CNC machining. It is the process of creating a program that will be used to control the CNC machine. This program will contain instructions for the machine to follow, such as the type of material to be machined, the cutting speed, the feed rate, and the tool path. Pre-programming ensures that the machine will produce the desired results and that the machining process will be efficient and accurate.

4.What are the different types of custom metal cnc machined parts factory machines available in the market?

We maintain a certain amount of R&D investment every year and continuously improve operational efficiency to provide better services to our cooperative customers. 1. Lathe CNC Machine: A lathe CNC machine is used for cutting, drilling, and turning metal parts. It is one of the most common types of CNC machines used in the manufacturing industry. 2. Milling CNC Machine: A milling CNC machine is used for cutting, drilling, and shaping metal parts. It is used for creating complex shapes and intricate details. 3. Plasma Cutting CNC Machine: A plasma cutting CNC machine is used for cutting metal parts with a high-temperature plasma arc. It is used for creating intricate shapes and details. 4. Laser Cutting CNC Machine: A laser cutting CNC machine is used for cutting metal parts with a high-powered laser beam. It is used for creating intricate shapes and details. 5. Waterjet Cutting CNC Machine: A waterjet cutting CNC machine is used for cutting metal parts with a high-pressure stream of water. It is used for creating intricate shapes and details.

5.Is it possible to produce prototypes with custom metal cnc machined parts factory machining?

Our company has many years of custom metal cnc machined parts factory experience and expertise. Yes, it is possible to produce prototypes with metal CNC machining. CNC machining is a process that uses computer numerical control (CNC) machines to cut and shape metal parts with precision. It is a popular choice for producing prototypes because it is fast, accurate, and cost-effective.

6.About custom metal cnc machined parts factory delivery date

The delivery date for metal CNC parts will depend on the complexity of the parts, the size of the order, and the availability of the materials. Generally, the delivery time for metal CNC parts can range from a few days to several weeks.

7.What are the different types of tool holders used in custom metal cnc machined parts factory machining?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. 1. Collet Chucks: Collet chucks are used to hold cylindrical tools such as drills, reamers, and taps. They are available in a variety of sizes and styles to accommodate different tool sizes and shapes. 2. End Mill Holders: End mill holders are used to hold end mills for machining operations. They are available in a variety of sizes and styles to accommodate different tool sizes and shapes. 3. Face Mill Holders: Face mill holders are used to hold face mills for machining operations. They are available in a variety of sizes and styles to accommodate different tool sizes and shapes. 4. Shell Mill Holders: Shell mill holders are used to hold shell mills for machining operations. They are available in a variety of sizes and styles to accommodate different tool sizes and shapes. 5. Tap Holders: Tap holders are used to hold taps for machining operations. They are available in a variety of sizes and styles to accommodate different tool sizes and shapes. 6. Tool Turrets: Tool turrets are used to hold multiple tools for machining operations. They are available in a variety of sizes and styles to accommodate different tool sizes and shapes.

8.About custom metal cnc machined parts factory production skills training

Metal CNC production skills training is a type of training that teaches individuals how to use CNC machines to produce metal parts. This type of training is typically offered by technical schools, community colleges, and other educational institutions. It can also be offered by companies that specialize in CNC production. The training typically covers topics such as machine setup, programming, and operation. It also covers safety procedures and quality control.

9.About custom metal cnc machined parts factory raw material procurement system

A metal CNC raw material procurement system is a computerized system that helps to streamline the process of purchasing raw materials for CNC machining. The system helps to automate the process of ordering, tracking, and managing the raw materials needed for CNC machining. It also helps to ensure that the right materials are ordered in the right quantities and at the right time. The system can also help to reduce costs associated with purchasing raw materials, as well as improve the efficiency of the CNC machining process.

10.How does the size of the cutting tool affect the accuracy of custom metal cnc machined parts factory machining?

We operate our custom metal cnc machined parts factory business with integrity and honesty. The size of the cutting tool affects the accuracy of metal CNC machining in several ways. A larger cutting tool will produce a larger cut, which can lead to inaccuracies if the part is not designed to accommodate the larger size. A smaller cutting tool will produce a more precise cut, but it may also require more passes to achieve the desired accuracy. Additionally, the size of the cutting tool will affect the speed of the machining process, as larger tools require more time to complete a cut.

11.What types of metals can be machined using CNC?

We adhere to the principle of quality first and have a complete production quality management system and quality inspection process. Common metals that can be machined using CNC include aluminum, brass, copper, steel, stainless steel, titanium, and magnesium.

12.About custom metal cnc machined parts factory production capacity

Metal CNC production capacity is determined by the size and complexity of the parts being produced, the type of CNC machine being used, and the number of machines available. Generally, CNC machines are capable of producing parts with high accuracy and repeatability, and can produce parts with complex geometries. The production capacity of a CNC machine is determined by the number of axes it has, the speed of the spindle, and the size of the workpiece. The production capacity of a CNC machine can be increased by adding additional machines or by increasing the speed of the spindle.

13.Is it possible to modify a program in real-time during custom metal cnc machined parts factory machining?

We have established a good reputation and reliable partnerships within the custom metal cnc machined parts factory industry. Yes, it is possible to modify a program in real-time during metal CNC machining. This is done by using a CNC control system that is capable of real-time editing. This allows the operator to make changes to the program while the machine is running, without having to stop the machine and restart the program.

14.About custom metal cnc machined parts factory inventory

Metal CNC inventory is a type of inventory that is used to store and manage metal parts and components that are used in CNC (Computer Numerical Control) machines. This type of inventory is typically used in manufacturing and engineering industries, as it allows for the efficient tracking and management of metal parts and components. Metal CNC inventory can include items such as screws, nuts, bolts, washers, and other metal components. It can also include raw materials such as steel, aluminum, and other metals.

15.What are the factors to consider when choosing the right spindle speed for custom metal cnc machined parts factory machining?

1. Material: The type of material being machined will determine the optimal spindle speed. Harder materials require slower speeds, while softer materials can be machined at higher speeds. 2. Tooling: The type of tooling being used will also affect the spindle speed. For example, a high-speed steel tool will require a higher spindle speed than a carbide tool. 3. Feed Rate: The feed rate of the tool will also affect the spindle speed. A higher feed rate will require a higher spindle speed. 4. Depth of Cut: The depth of cut will also affect the spindle speed. Deeper cuts require slower speeds, while shallow cuts can be machined at higher speeds. 5. Machine Capacity: The capacity of the machine will also affect the spindle speed. Machines with higher capacities can handle higher spindle speeds.

16.About custom metal cnc machined parts factory production management system

Metal CNC Production Management System is a software solution designed to help metalworking companies manage their CNC production processes. It provides a comprehensive set of tools to help streamline production, from scheduling and tracking jobs to managing inventory and quality control. The system also helps to reduce costs by providing real-time visibility into production processes and helping to identify areas of inefficiency. Additionally, the system can be used to generate reports and analyze data to help improve production processes.

17.What is the role of chip control in custom metal cnc machined parts factory machining?

As one of the top custom metal cnc machined parts factory manufacturers in China, we take this very seriously. Chip control is an important part of metal CNC machining. It is the process of controlling the size, shape, and volume of chips produced during the machining process. This is done by controlling the cutting speed, feed rate, and depth of cut. Chip control helps to reduce tool wear, improve surface finish, and increase the life of the cutting tool. It also helps to reduce the amount of time and energy required to complete the machining process.

18.Is it possible to perform reverse engineering using custom metal cnc machined parts factory machining?

Yes, it is possible to perform reverse engineering using metal CNC machining. This process involves taking a physical object and using a CNC machine to create a 3D model of the object. This model can then be used to create a new version of the object or to modify the existing object.