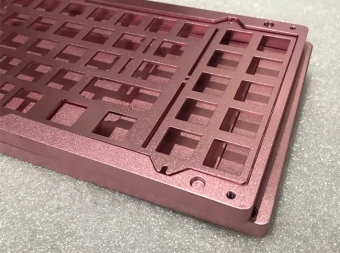

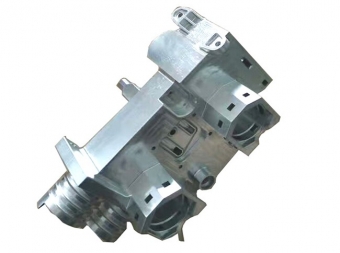

customize enclosure metal cnc (computer numerical control) machining is the process of using computer-aided design (CAD) models and computer-aided manufacturing (CAM) software to precisely control the movement of cutting tools on Chromium materials. This automation can produce high-precision and complex designs with minimal human intervention, resulting in a faster and more efficient production process.

The main advantage of customize enclosure metal cnc technology is the ability to produce parts with high precision, consistency and tight tolerances. This is achieved through the use of advanced software that controls the movement of CNC machine tools, allowing complex cuts and shapes to be achieved with precision. In addition to precision, customize enclosure metal cnc machines offer high levels of efficiency. By using computer programming, these machines can work continuously and quickly, reducing production time and costs. The versatility of customize enclosure metal cnc technology allows for the machining of a variety of materials, including steel, aluminum, Nickel, brass and titanium. This makes it a valuable tool in industries such as aerospace, automotive and medical that often use different types of metals. Some key parameters to consider when using customize enclosure metal cnc technology include the type of CNC machine being used, spindle speed, feed rate and depth of cut. These parameters can be adjusted and optimized to achieve the desired results, making it a highly customizable process.

| Place of Origin: | Xiamen, China. |

| Type: |

Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM |

| CNC Machining or Not: | Cnc Machining |

| Available Materials: | Plastic Metal Stainless Steel Copper Brass Titanium Aluminium |

| Surface Treatment: | Sandblasting,Plating,Anodizing,Dusting As Your Order |

| OEM/ODM: | OEM ODM CNC Machining Service |

| Processing: | CNC Machining Service |

| Processing Level: | 3 4 5 6 Axis CNC TURNING MILLING |

| Item Name: | Accept Custom Logo |

| Quality Control: | 100% Inspection Before Shipment |

| Certification: | ISO 9001:2015 |

| Supply Ability: | 5739898 Piece/Pieces per Week as per customized |

| Quantity (pieces) | > 1832 |

| Lead time (days) | To be negotiated |

customize enclosure metal cnc FAQs Guide. we will delve into the specifics of customize enclosure metal cnc machining and explore its advantages, applications, and key considerations for successful implementation. Whether you are new to the field or looking to expand your knowledge, this guide will provide a comprehensive overview of this revolutionary manufacturing process. So, let's begin our journey into the world of customize enclosure metal cnc machining!

1.Are there any environmental benefits to using customize enclosure metal cnc machining?

We continuously upgrade our skills and knowledge to adapt to changing customize enclosure metal cnc market needs. Yes, metal CNC machining can provide environmental benefits. CNC machining is a highly efficient process that produces very little waste, which helps to reduce the amount of material that needs to be disposed of. Additionally, CNC machining can be used to create parts with very precise tolerances, which can help to reduce the amount of energy needed to produce a part. Finally, CNC machining can be used to create parts with a longer lifespan, which can help to reduce the amount of materials that need to be replaced over time.

2.What is the maintenance routine for a customize enclosure metal cnc machine?

We operate our customize enclosure metal cnc business with integrity and honesty. 1. Clean the machine regularly. 2. Check the lubrication levels and top up as needed. 3. Check for any loose bolts or screws and tighten them. 4. Inspect the cutting tools for wear and replace as needed. 5. Check the coolant levels and top up as needed. 6. Check the spindle bearings for wear and replace as needed. 7. Check the electrical connections and wiring for any signs of damage or wear. 8. Check the machine for any signs of vibration or excessive noise. 9. Check the machine for any signs of overheating. 10. Check the machine for any signs of corrosion or rust.

3.Is it possible to perform multiple operations on a single piece using customize enclosure metal cnc machining?

Yes, it is possible to perform multiple operations on a single piece using metal CNC machining. Depending on the complexity of the part, multiple operations such as drilling, milling, turning, and tapping can be performed on a single piece.

4.Can customize enclosure metal cnc machines be used for both large and small scale production?

customize enclosure metal cnc is not a product only, but also can help you comes to money-making. Yes, metal CNC machines can be used for both large and small scale production. CNC machines are highly versatile and can be used to produce a wide range of products, from small components to large-scale parts. The size of the parts that can be produced is only limited by the size of the machine and the tools that are used.

5.Is it possible to modify a program in real-time during customize enclosure metal cnc machining?

We have established a good reputation and reliable partnerships within the customize enclosure metal cnc industry. Yes, it is possible to modify a program in real-time during metal CNC machining. This is done by using a CNC control system that is capable of real-time editing. This allows the operator to make changes to the program while the machine is running, without having to stop the machine and restart the program.

6.What are the environmental impacts of using different coolants in customize enclosure metal cnc machining?

The environmental impacts of using different coolants in metal CNC machining depend on the type of coolant used. Generally, coolants used in metal CNC machining can be divided into two categories: water-soluble and oil-based. Water-soluble coolants are generally considered to be more environmentally friendly than oil-based coolants. They are biodegradable and do not contain hazardous chemicals. However, they can still cause environmental damage if not disposed of properly. Oil-based coolants are not biodegradable and can contain hazardous chemicals. They can also cause air and water pollution if not disposed of properly. Additionally, they can be flammable and can cause fires if not handled properly.

7.About customize enclosure metal cnc quality system

Metal CNC quality systems are designed to ensure that the parts and components produced by CNC machines meet the highest standards of quality and accuracy. Quality systems typically include a set of processes and procedures that are used to monitor and control the quality of the parts and components produced. These processes and procedures may include quality control checks, inspections, and testing. Quality systems also typically include a system of documentation and records that are used to track and monitor the quality of the parts and components produced. Quality systems are essential for ensuring that CNC parts and components meet the highest standards of quality and accuracy.

8.What are the advantages of using customize enclosure metal cnc over traditional machining methods?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. 1. Increased Precision: CNC machining offers greater precision than traditional machining methods, allowing for more accurate parts with tighter tolerances. 2. Increased Speed: CNC machining can produce parts faster than traditional machining methods, allowing for faster production times. 3. Increased Versatility: CNC machining can be used to produce a wide variety of parts with complex geometries, allowing for greater design flexibility. 4. Reduced Waste: CNC machining produces less waste than traditional machining methods, resulting in lower material costs. 5. Improved Safety: CNC machining eliminates the need for manual labor, reducing the risk of injury.

9.What is the role of the spindle speed in customize enclosure metal cnc machining?

We are a professional customize enclosure metal cnc company dedicated to providing high quality products and services. The spindle speed is an important factor in metal CNC machining. It determines the speed at which the cutting tool moves across the material, and affects the quality of the finished product. A higher spindle speed will result in a faster cutting process, but can also cause the cutting tool to wear out faster. A lower spindle speed will result in a slower cutting process, but will also reduce the wear on the cutting tool. The spindle speed must be carefully adjusted to ensure the best results.

10.What are the different types of tool changes used in customize enclosure metal cnc machining?

1. Manual Tool Change: This is the most basic type of tool change and involves manually exchanging the cutting tool by hand. 2. Automatic Tool Change: This type of tool change is automated and is typically used in CNC machining centers. The tool is automatically exchanged by a robotic arm or a tool changer. 3. Quick Change Tooling: This type of tool change is used in CNC lathes and involves a quick-change tool holder that allows for rapid tool changes. 4. Tool Presetter: This type of tool change is used in CNC machining centers and involves a tool presetter that measures the tool and sets it to the correct position before it is used.

11.What safety precautions should be taken when handling metal pieces in a CNC machine?

We are a professional customize enclosure metal cnc company dedicated to providing high quality products and services. 1. Wear protective clothing, such as safety glasses, gloves, and a face shield. 2. Ensure that the machine is properly grounded and that all electrical components are in good working order. 3. Make sure that the machine is properly lubricated and that all moving parts are free of debris. 4. Keep hands and other body parts away from the cutting area. 5. Use a vacuum to collect any metal chips or shavings that may be created during the machining process. 6. Make sure that the cutting tools are sharp and in good condition. 7. Use a coolant to reduce heat buildup and to reduce the risk of fire. 8. Make sure that the workpiece is securely clamped in place before machining. 9. Make sure that the machine is turned off and unplugged when not in use. 10. Make sure that the machine is properly maintained and inspected regularly.

12.About customize enclosure metal cnc production management system

Metal CNC Production Management System is a software solution designed to help metalworking companies manage their CNC production processes. It provides a comprehensive set of tools to help streamline production, from scheduling and tracking jobs to managing inventory and quality control. The system also helps to reduce costs by providing real-time visibility into production processes and helping to identify areas of inefficiency. Additionally, the system can be used to generate reports and analyze data to help improve production processes.

13.About customize enclosure metal cnc overseas warehouse

Metal CNC overseas warehouses are warehouses located in foreign countries that specialize in the storage and distribution of metal CNC parts and components. These warehouses are typically owned and operated by a metal CNC manufacturer or distributor, and they provide a convenient way for customers to access parts and components from around the world. Metal CNC overseas warehouses are often located in countries with lower labor costs, allowing manufacturers to reduce their overhead costs and pass those savings on to their customers.

14.What are the advantages of using a multi-axis customize enclosure metal cnc machine?

Being one of the top customize enclosure metal cnc manufacturers in China, We attach great importance to this detail. 1. Increased accuracy: Multi-axis CNC machines are capable of producing parts with greater accuracy than traditional machining methods. 2. Increased speed: Multi-axis CNC machines can produce parts faster than traditional machining methods. 3. Increased flexibility: Multi-axis CNC machines can be programmed to produce parts with complex geometries and shapes. 4. Increased productivity: Multi-axis CNC machines can produce multiple parts in a single setup, reducing setup time and increasing productivity. 5. Reduced waste: Multi-axis CNC machines can produce parts with minimal waste, reducing material costs. 6. Reduced labor costs: Multi-axis CNC machines can reduce labor costs by eliminating the need for manual labor.

15.About the scale of customize enclosure metal cnc factory

The size of a metal CNC factory depends on the type of products it produces and the size of its customer base. A small factory may only have a few CNC machines and a few employees, while a larger factory may have dozens of CNC machines and hundreds of employees. The size of the factory also depends on the type of materials it works with, as some materials require more specialized equipment than others.