As technology continues to advance, the manufacturing industry is undergoing a digital revolution. In the midst of this transformative wave, metal Computer Numerical Control (CNC) machines have emerged as treasures of manufacturing due to their high precision, efficiency, and flexibility. Xiamen Wiesel Technology Co., Ltd. article delves deep into the principles of metal CNC technology, explores its applications, and examines its impact on the future of manufacturing.

1. Principles of Metal CNC

Metal CNC is a type of computer numerical control technology-based machine tool. Its core principle involves controlling the motion of tools on the machine by pre-programmed instructions, enabling precise machining of workpieces. Compared to traditional machine tools, metal CNC boasts a higher level of automation and greater flexibility, ushering in a new era of manufacturing precision and efficiency.

2. Evolution of Metal CNC Technology

The journey of metal CNC technology traces back to its humble beginnings, where manual machining dominated the manufacturing landscape. Over time, the advent of computer technology paved the way for numerical control, marking a significant leap in precision and repeatability. As computing power continued to grow, metal CNC machines evolved to integrate complex algorithms, providing unprecedented control over machining processes.

3. Applications Across Industries

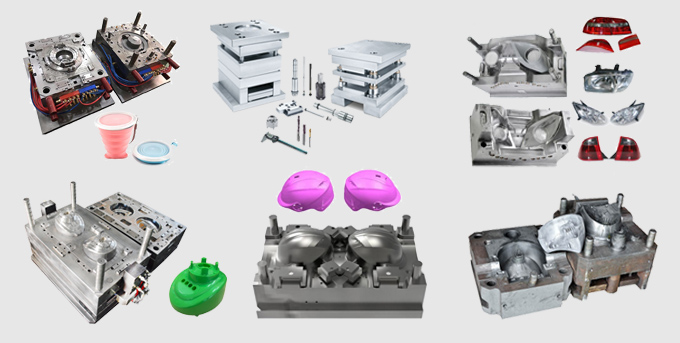

Metal CNC machines find applications across a spectrum of industries, from aerospace and automotive to healthcare and consumer electronics. In aerospace, for example, the demand for lightweight yet structurally robust components has driven the adoption of metal CNC for precision machining of aircraft parts. Similarly, in the automotive sector, the production of intricate engine components and body parts relies heavily on the capabilities of metal CNC machines.

In the medical field, metal CNC plays a crucial role in the manufacturing of customized implants and prosthetics, where precision is paramount. The consumer electronics industry benefits from metal CNC in the production of intricate components for devices such as smartphones and laptops. The versatility of metal CNC technology allows it to adapt to the unique requirements of each industry, showcasing its significance in the modern manufacturing landscape.

4. Advantages of Metal CNC

The widespread adoption of metal CNC machines can be attributed to their numerous advantages. Firstly, these machines offer unparalleled precision, allowing for the creation of intricate and complex geometries with tight tolerances. The automation of the machining process not only enhances efficiency but also reduces the risk of human error, resulting in higher-quality end products.

Flexibility is another key advantage of metal CNC. With the ability to quickly reprogram the machines for different tasks, manufacturers can adapt to changing production requirements without the need for extensive retooling. This adaptability is particularly valuable in industries where product lifecycles are short, and rapid prototyping and production are essential.

5. Future Trends in Metal CNC

Looking ahead, several trends are poised to shape the future of metal CNC technology. One such trend is the integration of artificial intelligence (AI) and machine learning (ML) algorithms into CNC systems. This integration enables real-time monitoring and adjustment of machining processes, optimizing efficiency and minimizing waste.

Furthermore, the concept of "lights-out manufacturing" is gaining traction in the industry. This involves unmanned operation of CNC machines, allowing for continuous production without the need for human intervention. Advanced sensors and automated quality control systems contribute to the realization of lights-out manufacturing, promising increased productivity and cost savings.

The ongoing development of hybrid manufacturing, combining additive and subtractive processes, is another notable trend. Metal CNC machines are increasingly being integrated with 3D printing technology, enabling the creation of complex components with enhanced structural integrity. This convergence of technologies opens up new possibilities for the production of customized and highly optimized parts.

6. Challenges and Considerations

Despite the remarkable advancements, challenges persist in the realm of metal CNC. The initial cost of acquiring and setting up CNC machines can be substantial, posing a barrier to entry for small and medium-sized enterprises. Additionally, the need for skilled operators and programmers capable of harnessing the full potential of these machines remains a challenge.

Cybersecurity concerns also come to the forefront, as the increasing connectivity of CNC machines introduces potential vulnerabilities. Securing these systems against cyber threats is crucial to ensuring the integrity of manufacturing processes and protecting valuable intellectual property.

In conclusion, metal CNC technology stands at the forefront of the digital manufacturing revolution, reshaping the way products are designed and produced. Its precision, efficiency, and adaptability have propelled it into various industries, driving innovation and setting new standards for manufacturing excellence. As technology continues to evolve, the future holds exciting possibilities for metal CNC, with advancements in AI, lights-out manufacturing, and hybrid processes promising to further elevate its capabilities. Embracing these trends and addressing associated challenges will be key to unlocking the full potential of metal CNC in the years to come.

metal cnc--An Ultimate FAQ Guide:

• What are metal cnc products?

Metal CNC products refer to products that use numerical control (CNC) technology to process metal materials, with higher precision and quality than traditional processing methods.

• What are the advantages of Metal CNC products?

Metal CNC products have the advantages of high precision, fast processing speed, good repeatability, strong durability, and high production efficiency.

• What is the important role of CNC processing in metal products?

CNC machining can realize complex machining tasks, allowing metal products of almost any shape to be easily processed while ensuring accuracy and quality.

• What metal materials can be processed by Metal CNC products?

Metal CNC products can process a variety of metal materials, including aluminum, copper, iron, steel, stainless steel, titanium, magnesium, etc.

• What is the maximum size limit for Metal CNC product processing?

The maximum size of Metal CNC product processing depends on the specifications and model of the CNC machining center, and generally can reach a size range of several meters.

• How to ensure the accuracy of Metal CNC products?

Because CNC machining is controlled by a computer, its accuracy can reach thousands of millimeters, which is much higher than traditional machining methods.

• Do Metal CNC products require manual operation?

CNC machining centers need to be set up and monitored by operators, but the entire processing process is automatically completed by the machine. The operator's role is mainly debugging and inspection.

• Compared with metal CNC products and traditional processing methods, which one saves more time and cost?

Because Metal CNC products can realize automated processing, they can save a lot of time and labor costs, and the processing quality is also better.

• What is the surface finish of Metal CNC products?

Since CNC machining is cutting with CNC tools, its processing surface is flatter and has a higher finish than traditional methods.

• In what fields can Metal CNC products be applied?

Metal CNC products are widely used in automobile manufacturing, aerospace, shipbuilding, machinery manufacturing, medical equipment, electronic products and other fields, bringing higher production efficiency and quality to these industries.