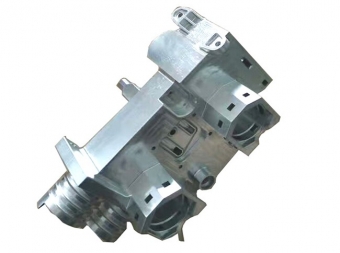

metal cnc technology is a precision machining process that uses computer numerical control (CNC) to control and operate industrial-grade machinery to manufacture high-quality metal parts and products. This advanced technology offers a range of advantages over traditional manual machining methods, including greater accuracy, repeatability and efficiency.

At metal cnc, we prioritize quality and adhere to strict quality control procedures to ensure that every product meets or exceeds customer expectations. We also offer various secondary processes, such as heat treating, anodizing, and plating, to provide a complete solution from design to finished product. Whether you need prototypes, small batches, or large-scale production, metal cnc has the capability and expertise to fulfill your metal machining needs. Our dedication to using the latest technology and our commitment to delivering exceptional results make us the preferred choice for metal CNC services.

| CNC Machining or Not | metal cnc |

| Material Capabilities | Aluminum, Brass, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys |

| Type | Laser Machining, Milling, Other Machining Services, Turning, Rapid Prototyping |

| Surface treatment | Color Anodize,Sandblasting,Powder Coating,Electroplating,Zink Plating |

| Tolerance | 0.002-0.01mm |

| Process | Cnc Machining + Surface Treatment |

| Equipment | Milling Machine :3/4/5 Axis CNC Machining Center:Turning Centre |

| Quality Control | ISO/TS9001 |

| Name | Custom Machining Metal Parts Service |

| Place of Origin | China |

metal cnc FAQs Guide. we will delve into the specifics of metal cnc machining and explore its advantages, applications, and key considerations for successful implementation. Whether you are new to the field or looking to expand your knowledge, this guide will provide a comprehensive overview of this revolutionary manufacturing process. So, let's begin our journey into the world of metal cnc machining!

1.Can metal cnc machines be used for both high and low volume production?

Yes, metal CNC machines can be used for both high and low volume production. CNC machines are highly versatile and can be programmed to produce a wide range of parts in both high and low volumes. They are also capable of producing parts with high precision and repeatability, making them ideal for both high and low volume production.

2.What are the advantages of using metal cnc over traditional machining methods?

We focus on our customers' needs and strive to meet their expectations, so we take this very seriously. 1. Increased Precision: CNC machining offers greater precision than traditional machining methods, allowing for more accurate parts with tighter tolerances. 2. Increased Speed: CNC machining can produce parts faster than traditional machining methods, allowing for faster production times. 3. Increased Versatility: CNC machining can be used to produce a wide variety of parts with complex geometries, allowing for greater design flexibility. 4. Reduced Waste: CNC machining produces less waste than traditional machining methods, resulting in lower material costs. 5. Improved Safety: CNC machining eliminates the need for manual labor, reducing the risk of injury.

3.About metal cnc overseas warehouse

Metal CNC overseas warehouses are warehouses located in foreign countries that specialize in the storage and distribution of metal CNC parts and components. These warehouses are typically owned and operated by a metal CNC manufacturer or distributor, and they provide a convenient way for customers to access parts and components from around the world. Metal CNC overseas warehouses are often located in countries with lower labor costs, allowing manufacturers to reduce their overhead costs and pass those savings on to their customers.

4.About metal cnc production management system

Metal CNC Production Management System is a software solution designed to help metalworking companies manage their CNC production processes. It provides a comprehensive set of tools to help streamline production, from scheduling and tracking jobs to managing inventory and quality control. The system also helps to reduce costs by providing real-time visibility into production processes and helping to identify areas of inefficiency. Additionally, the system can be used to generate reports and analyze data to help improve production processes.

5.About metal cnc production capacity

Metal CNC production capacity is determined by the size and complexity of the parts being produced, the type of CNC machine being used, and the number of machines available. Generally, CNC machines are capable of producing parts with high accuracy and repeatability, and can produce parts with complex geometries. The production capacity of a CNC machine is determined by the number of axes it has, the speed of the spindle, and the size of the workpiece. The production capacity of a CNC machine can be increased by adding additional machines or by increasing the speed of the spindle.

6.Are there any environmental benefits to using metal cnc machining?

We continuously upgrade our skills and knowledge to adapt to changing metal cnc market needs. Yes, metal CNC machining can provide environmental benefits. CNC machining is a highly efficient process that produces very little waste, which helps to reduce the amount of material that needs to be disposed of. Additionally, CNC machining can be used to create parts with very precise tolerances, which can help to reduce the amount of energy needed to produce a part. Finally, CNC machining can be used to create parts with a longer lifespan, which can help to reduce the amount of materials that need to be replaced over time.

7.Are there any limitations to the size of the metal piece that can be machined with CNC?

As one of the metal cnc market leaders, we are known for innovation and reliability. Yes, there are limitations to the size of the metal piece that can be machined with CNC. The size of the metal piece is limited by the size of the CNC machine, the size of the cutting tool, and the size of the workpiece. Additionally, the complexity of the part and the type of material being machined can also affect the size of the metal piece that can be machined.

8.Is it possible to add threading to a metal piece using CNC?

As one of the top metal cnc manufacturers in China, we take this very seriously. Yes, it is possible to add threading to a metal piece using CNC. This is done by using a threading tool, which is a specialized cutting tool designed to cut threads into a workpiece. The threading tool is mounted in the spindle of the CNC machine and is programmed to cut the desired thread profile into the workpiece.

9.How does the selection of the correct tool path affect the outcome of metal cnc machining?

The selection of the correct tool path is critical to the success of metal CNC machining. The tool path determines the direction and speed of the cutting tool, as well as the amount of material that is removed. If the wrong tool path is chosen, the machined part may not meet the desired specifications, or the cutting tool may be damaged. Additionally, the wrong tool path can lead to an inefficient machining process, resulting in increased production costs.

10.How accurate is the precision of metal cnc machining?

We focus on teamwork and communication to achieve common goals, We attach great importance to this detail. The precision of metal CNC machining is typically very high, with tolerances of up to 0.001 inches (0.025 mm) achievable. However, the accuracy of the machining process depends on a variety of factors, including the quality of the machine, the skill of the operator, and the type of material being machined.

11.What is the role of the spindle speed in metal cnc machining?

We are a professional metal cnc company dedicated to providing high quality products and services. The spindle speed is an important factor in metal CNC machining. It determines the speed at which the cutting tool moves across the material, and affects the quality of the finished product. A higher spindle speed will result in a faster cutting process, but can also cause the cutting tool to wear out faster. A lower spindle speed will result in a slower cutting process, but will also reduce the wear on the cutting tool. The spindle speed must be carefully adjusted to ensure the best results.

12.Can metal cnc machines produce high-quality surface finishes?

As one of the metal cnc market leaders, we are known for innovation and reliability. Yes, metal CNC machines can produce high-quality surface finishes. CNC machines are capable of producing very precise and accurate parts with smooth surfaces. The quality of the surface finish depends on the type of tooling used, the speed and feed rate of the machine, and the type of material being machined.

13.What are the advantages of using a gantry-style metal cnc machine?

1. High precision: Gantry-style metal CNC machines are designed to provide high precision and accuracy, allowing for complex and intricate designs to be created with ease. 2. Versatility: Gantry-style metal CNC machines are highly versatile and can be used for a variety of applications, including cutting, drilling, milling, and engraving. 3. Cost-effectiveness: Gantry-style metal CNC machines are cost-effective and can be used to produce large quantities of parts in a short amount of time. 4. Durability: Gantry-style metal CNC machines are designed to be durable and can withstand heavy use and wear and tear. 5. Safety: Gantry-style metal CNC machines are designed with safety features to protect operators from potential hazards.

14.What is the role of coolant in reducing heat and friction during metal cnc machining?

Our metal cnc products undergo strict quality control to ensure customer satisfaction. Coolant plays an important role in reducing heat and friction during metal CNC machining. Coolant helps to reduce the temperature of the cutting tool and the workpiece, which helps to reduce the amount of heat generated during the machining process. Coolant also helps to reduce friction between the cutting tool and the workpiece, which helps to reduce wear and tear on the cutting tool and the workpiece. Additionally, coolant helps to flush away chips and debris from the cutting area, which helps to reduce the risk of clogging and jamming.

15.What are the environmental impacts of using different coolants in metal cnc machining?

The environmental impacts of using different coolants in metal CNC machining depend on the type of coolant used. Generally, coolants used in metal CNC machining can be divided into two categories: water-soluble and oil-based. Water-soluble coolants are generally considered to be more environmentally friendly than oil-based coolants. They are biodegradable and do not contain hazardous chemicals. However, they can still cause environmental damage if not disposed of properly. Oil-based coolants are not biodegradable and can contain hazardous chemicals. They can also cause air and water pollution if not disposed of properly. Additionally, they can be flammable and can cause fires if not handled properly.

16.What is the maintenance routine for a metal cnc machine?

We operate our metal cnc business with integrity and honesty. 1. Clean the machine regularly. 2. Check the lubrication levels and top up as needed. 3. Check for any loose bolts or screws and tighten them. 4. Inspect the cutting tools for wear and replace as needed. 5. Check the coolant levels and top up as needed. 6. Check the spindle bearings for wear and replace as needed. 7. Check the electrical connections and wiring for any signs of damage or wear. 8. Check the machine for any signs of vibration or excessive noise. 9. Check the machine for any signs of overheating. 10. Check the machine for any signs of corrosion or rust.