Injectiong Molding Defects Caused by Molding Process

Certain injection molding processes may not be effective for the production of some parts. The molding process is the leading cause of defects in injection molding parts. However, you can easily prevent such defects by simply adjusting the temperature, flow rate, or other mold parameters. These defects include the following:

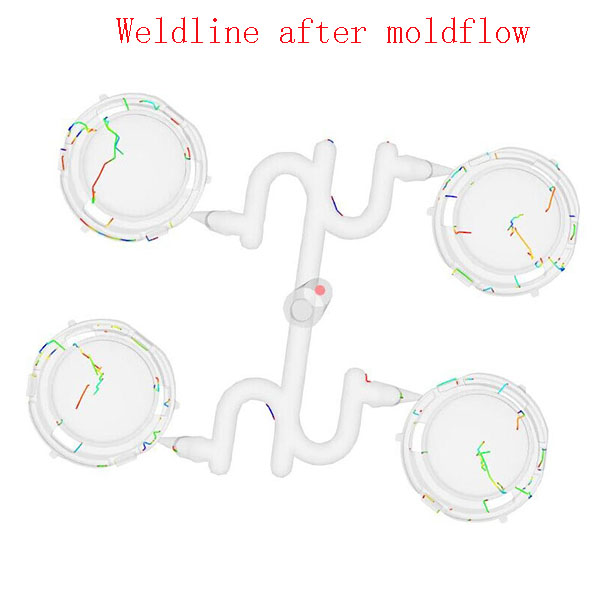

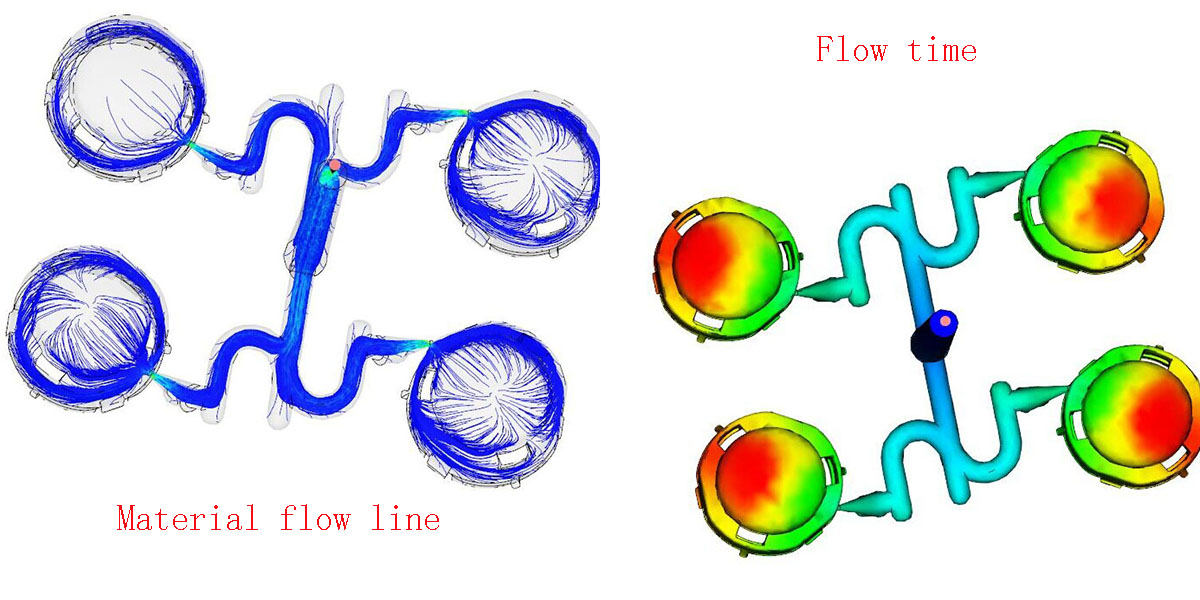

Welding Line are plastic molded part defects that cause a convergence of molten material on the surface of part (like the below picture)

Why has the defects of the part after injecting:

> A too low or too high temperature of molten material

>Uneven wall thickness

>Insert ,holes, and multi-gate features on fabricated parts.

How to avoid the defects before mold ?

a.Good structure Design for the part

b.Make Moldflow Anaylsis before mold design.