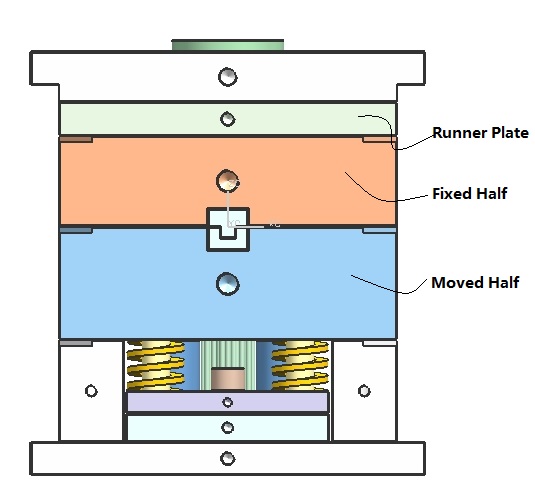

How Does Three Plate Injection Mold Work

Three Plate Injection Mold is a common injection mold ,it consists three parts: Fixed Half, Moved Half, Runner Plate. Three Plate Molding Process is completed by two times of closing and opening when injecting. When opening, runner plate is first time, then moved half is second; When closing, Moved half is first time, runner Plate is second.

The following is the main working principle:

⇒Mold Closed: At the begining of the injection cycle, the moved and fixed half will be retatively closed ,sealing the mold of cavity and

core a closed space

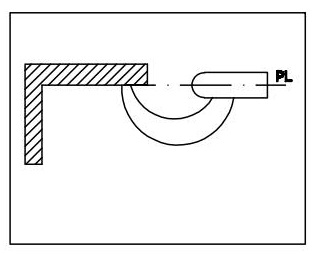

⇒Plastic Injection: After mold is closed, the melted plastic is injected into the nozzle of the injection machine, and the melted plastic is

injected into the mold cavity through high pressure

⇒Plastic Filling: Injection machine inject molten plastic into the mold, filling the ful space of mold cavity. Plastic cools and solidifies in

the mold, gradually forming the shape of plastic products

⇒Cooling: After the completion of plastic filling, the cooling system starts to work, and the cooling and solidification process of the platic is accelerated by circulating the cooling medium ( normally water)

⇒Mold Opened: When plastic is fully cooled and solidified, the moved and fixed half will separate and open, part is enjected from the mold

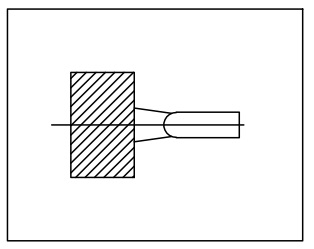

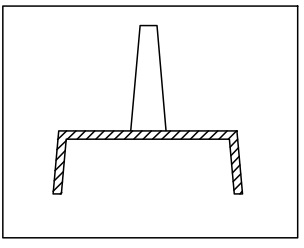

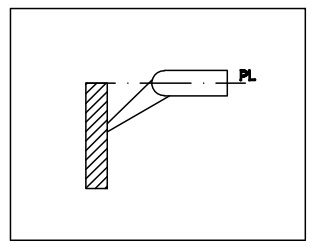

Main Type of Gating For Two Plate Mold

|

|

|

|

| Side Gating | Direct Gating | Sub Gating | Banana Gating |

What's the Advantage of Three Plate Mold

|

Simple Structure:Two plate injection mold is composed of two halves,with only one movable half between fixed and removed half. The structure is simple and clear,making it easy to maintain and operate

|

High Space Utilization: The fixed and moved half of the two plate injection mold is vertical separation. Compared with the injection mold construction with other structures, the two plate injection mold is more compact in size and more efficient in space utilization.

|

|

Wide Application : Two Plate injection mold is suitable for situations when injection molded parts are relatively simple and small mass production. Specific application areas include electronic products, plastic parts, daily necessities,etc

|

Easy Ejection: Due to the large opening and convenient opening-closing , the ejection speed of the two plate injection mold during the injection molding process will be faster, which is beneficial for improving production efficiency.

|