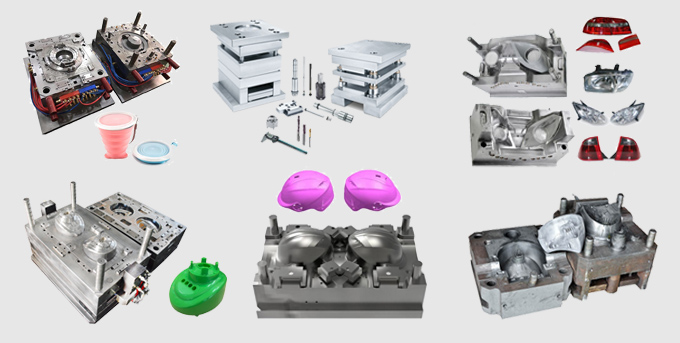

Xiamen Wiesel Technology Co., Ltd. is a manufacturer specializing in the production of precision metal parts for the automotive, aerospace, and medical industries. We have a strong R&D team and advanced CNC machine tools that can produce complex, high-precision parts. Wiesel has passed ISO9001 and ISO TS16949 certification to ensure product quality and reliability. We have been committed to technology promotion, R&D team training, and new process development.

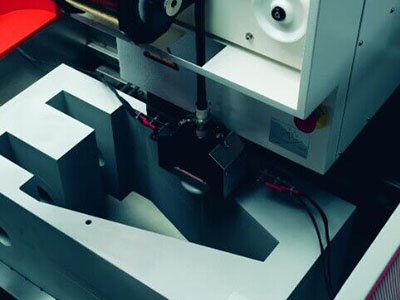

Metal CNC technology can be used to process a variety of metal materials, including aluminum, copper, steel, stainless steel, etc., with a wide range of applications. It is also highly flexible and can process various complex shapes according to design requirements to meet the needs of different customers. The advantages of Metal CNC technology also include high efficiency and high stability. It can process multiple parts at the same time, improve processing efficiency and reduce production costs. Moreover, the use of high-quality cutting tools and materials ensures stable and reliable processing quality and greatly reduces product quality defects.

about 3 axis metal cnc, we have carefully prepared some relevant professional knowledge documents for you, {hope to provide some help to you who are interested in cnc turning metal parts

Metal CNC technology is a high-precision, high-efficiency processing technology that achieves precise processing of metal materials through a digital control system, greatly improving production efficiency. The use of Metal CNC technology can save a lot of time and labor costs while ensuring product quality and stability, thus bringing huge production benefits to the enterprise. Whether it is in the automotive, aerospace, electronic equipment and other industries, or in the manufacturing of furniture, lamps, etc. in daily life, all can benefit from the high efficiency and high precision brought by Metal CNC technology, bringing convenience and quality to the development of society and life. Assure.

With the continuous development of modern technology, CNC technology is receiving more and more attention. In the manufacturing process of various mechanical equipment, the application of Metal CNC technology has become an indispensable part. Compared with traditional processing methods, Metal CNC technology has higher accuracy and efficiency, and more importantly, its super durability. Through the precise cutting and engraving of metal materials, Metal CNC technology can produce precise and durable parts, thereby increasing the service life and performance of equipment. Whether it is automobiles, aircraft or electronic products, Metal CNC technology plays an important role in providing a stable and reliable foundation for the development of all walks of life. It is precisely because of its long-term advantages that Metal CNC technology is becoming the mainstream of modern manufacturing, bringing us more and better products and services.

Metal CNC--An Ultimate FAQ Guide.

1.What is the role of chip control in metal CNC machining?

Chip control is an important part of metal CNC machining. It is the process of controlling the size, shape, and volume of chips produced during the machining process. This is done by controlling the cutting speed, feed rate, and depth of cut. Chip control helps to reduce the amount of heat generated during the machining process, which can cause tool wear and reduce the quality of the finished product. It also helps to reduce the amount of time needed to complete the machining process.

2.How does the cutting speed affect the temperature and surface finish in metal CNC machining?

The cutting speed affects the temperature and surface finish in metal CNC machining in several ways. A higher cutting speed will generate more heat due to increased friction between the cutting tool and the workpiece. This can lead to increased tool wear, reduced tool life, and poor surface finish. A lower cutting speed will reduce the amount of heat generated, resulting in improved tool life and better surface finish. Additionally, a lower cutting speed will reduce the risk of thermal deformation of the workpiece.

3.What is the maintenance routine for a metal CNC machine?

1. Clean the machine regularly. 2. Check the lubrication levels and top up as needed. 3. Check for any loose bolts or screws and tighten them. 4. Inspect the cutting tools for wear and replace as needed. 5. Check the coolant levels and top up as needed. 6. Check the spindle bearings for wear and replace as needed. 7. Check the electrical connections and wiring for any signs of damage or wear. 8. Check the machine for any signs of vibration or excessive noise. 9. Check the machine for any signs of overheating. 10. Check the machine for any signs of corrosion or rust.

4.How does the machine's rigidity affect the speed and accuracy of metal CNC machining?

The rigidity of the machine affects the speed and accuracy of metal CNC machining in several ways. A more rigid machine will be able to handle higher cutting forces, allowing for faster cutting speeds and more accurate cuts. A more rigid machine will also be less prone to vibration, which can cause inaccuracies in the finished product. Additionally, a more rigid machine will be able to hold tighter tolerances, resulting in more precise parts.

5.What is the role of coolant in metal CNC machining?

Coolant plays an important role in metal CNC machining. It helps to reduce friction between the cutting tool and the workpiece, which helps to improve the cutting performance and extend the life of the cutting tool. Coolant also helps to reduce heat generated during the machining process, which helps to prevent the workpiece from warping or cracking. Additionally, coolant helps to flush away chips and debris from the cutting area, which helps to improve the surface finish of the machined part.

6.What are the common applications of metal CNC machining in the aerospace industry?

1. Aircraft engine components: CNC machining is used to create components for aircraft engines, such as turbine blades, compressor blades, and other engine components. 2. Aircraft structural components: CNC machining is used to create components for aircraft structures, such as fuselage frames, wing spars, and other structural components. 3. Aircraft landing gear components: CNC machining is used to create components for aircraft landing gear, such as landing gear struts, wheels, and other components. 4. Aircraft interior components: CNC machining is used to create components for aircraft interiors, such as cabin walls, seats, and other interior components. 5. Aircraft instrumentation components: CNC machining is used to create components for aircraft instrumentation, such as navigation systems, autopilot systems, and other instrumentation components.

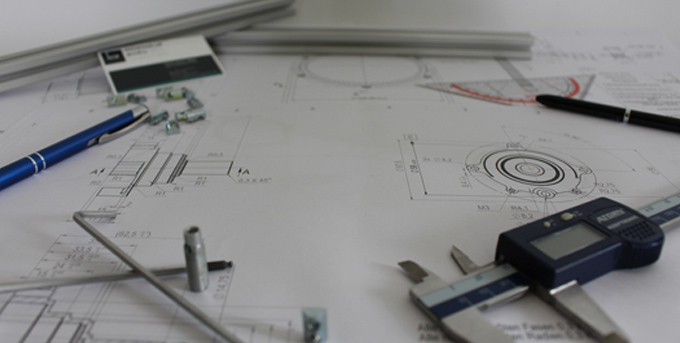

7.What is the role of CAM software in metal CNC machining?

CAM software is used to create the instructions for the CNC machine to follow when machining metal. It is used to create the toolpaths that the machine will use to cut the metal, as well as to set the speeds and feeds for the cutting tools. It also helps to optimize the machining process by ensuring that the cutting tools are used in the most efficient way possible.

8.Can metal CNC machines be used for both large and small scale production?

Yes, metal CNC machines can be used for both large and small scale production. CNC machines are highly versatile and can be used to produce a wide variety of products, from small components to large-scale parts. The size of the parts that can be produced is only limited by the size of the machine and the size of the tools used.

9.Is it possible to create complex shapes with metal CNC machining?

Yes, it is possible to create complex shapes with metal CNC machining. CNC machining is a process that uses computer-controlled cutting tools to shape metal into a desired shape. CNC machining can be used to create complex shapes with intricate details, such as curved surfaces, holes, and slots.

10.What is the definition of metal CNC?

Metal CNC (Computer Numerical Control) is a manufacturing process that uses computer-controlled machines to cut and shape metal parts with precision. It is used to create complex shapes and components with a high degree of accuracy and repeatability.

11.What is the role of coolant in reducing heat and friction during metal CNC machining?

Coolant plays an important role in reducing heat and friction during metal CNC machining. Coolant helps to reduce the temperature of the cutting tool and the workpiece, which helps to reduce the amount of heat generated during the machining process. Coolant also helps to reduce friction between the cutting tool and the workpiece, which helps to reduce wear and tear on the cutting tool and the workpiece. Additionally, coolant helps to flush away chips and debris from the cutting area, which helps to reduce the risk of clogging and jamming.

12.About the development history of metal cnc factory

Metal CNC factories have been around since the early 1950s. The first CNC machines were developed in the United States by John T. Parsons and John H. Parsons. These machines were used to produce precision parts for the aerospace industry. In the 1960s, CNC machines began to be used in the automotive industry, and by the 1970s, CNC machines were being used in a variety of industries. Today, CNC machines are used in a wide range of industries, from aerospace to medical to automotive. CNC machines are used to produce parts with high precision and accuracy, and they are used in a variety of applications, from prototyping to production.

13.What is the difference between CNC milling and CNC turning?

CNC milling is a machining process that uses computer numerical control (CNC) to control the movement of a cutting tool to shape a workpiece. It is used to create complex shapes and features in a variety of materials. CNC turning is a machining process that uses computer numerical control (CNC) to control the movement of a cutting tool to shape a workpiece. It is used to create cylindrical parts with a rotating cutting tool.

14.About metal cnc customization services

Metal CNC customization services are a great way to create custom parts and components for a variety of applications. CNC stands for Computer Numerical Control, and it is a process that uses computer-controlled machines to cut and shape metal into the desired shape. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and industrial. CNC customization services can provide custom parts and components that are designed to meet the exact specifications of the customer. These services can also provide a variety of finishes, such as anodizing, powder coating, and plating. CNC customization services can also provide a variety of machining services, such as drilling, tapping, and milling.

15.How does the material selection affect the performance of a metal CNC machine?

The material selection for a metal CNC machine affects its performance in several ways. The material chosen for the machine's components must be strong enough to withstand the forces of machining, as well as the heat generated during the process. Additionally, the material must be able to withstand the wear and tear of the machining process. The material must also be able to resist corrosion and other environmental factors. Finally, the material must be able to provide the necessary lubrication and cooling for the machine.

16.How does the programming process differ between different metal CNC machines?

The programming process for different metal CNC machines can vary depending on the type of machine and the complexity of the job. Generally, the programming process involves creating a program that tells the machine how to move and what operations to perform. This program is typically written in a language specific to the machine, such as G-code or Fanuc. The program is then loaded into the machine’s controller, which interprets the instructions and controls the machine’s movements. Depending on the type of machine, the programming process may also involve setting up the machine’s tooling, setting the cutting parameters, and running a test program to ensure the machine is functioning correctly.

17.What are the most commonly used cutting tools in metal CNC machining?

1. End Mills: End mills are the most commonly used cutting tools in metal CNC machining. They are used to cut slots, pockets, and contours in a variety of materials. 2. Drills: Drills are used to create holes in a variety of materials. They are available in a variety of sizes and shapes to accommodate different applications. 3. Reamers: Reamers are used to enlarge existing holes in a variety of materials. They are available in a variety of sizes and shapes to accommodate different applications. 4. Taps: Taps are used to create internal threads in a variety of materials. They are available in a variety of sizes and shapes to accommodate different applications. 5. Countersinks: Countersinks are used to create a conical shape in a variety of materials. They are available in a variety of sizes and shapes to accommodate different applications.

18.How does the material selection affect the cutting speed and feed rate in metal CNC machining?

The material selection affects the cutting speed and feed rate in metal CNC machining in several ways. Harder materials require higher cutting speeds and lower feed rates, while softer materials require lower cutting speeds and higher feed rates. The type of cutting tool used also affects the cutting speed and feed rate. For example, a high-speed steel tool will require a higher cutting speed and lower feed rate than a carbide tool. Additionally, the type of cutting fluid used can also affect the cutting speed and feed rate.

Tag:cnc laser cutting metal,3 axis metal cnc,cnc sheet metal forming,china cnc sheet metal fabrication,cnc metal cut